The Art of Engineering

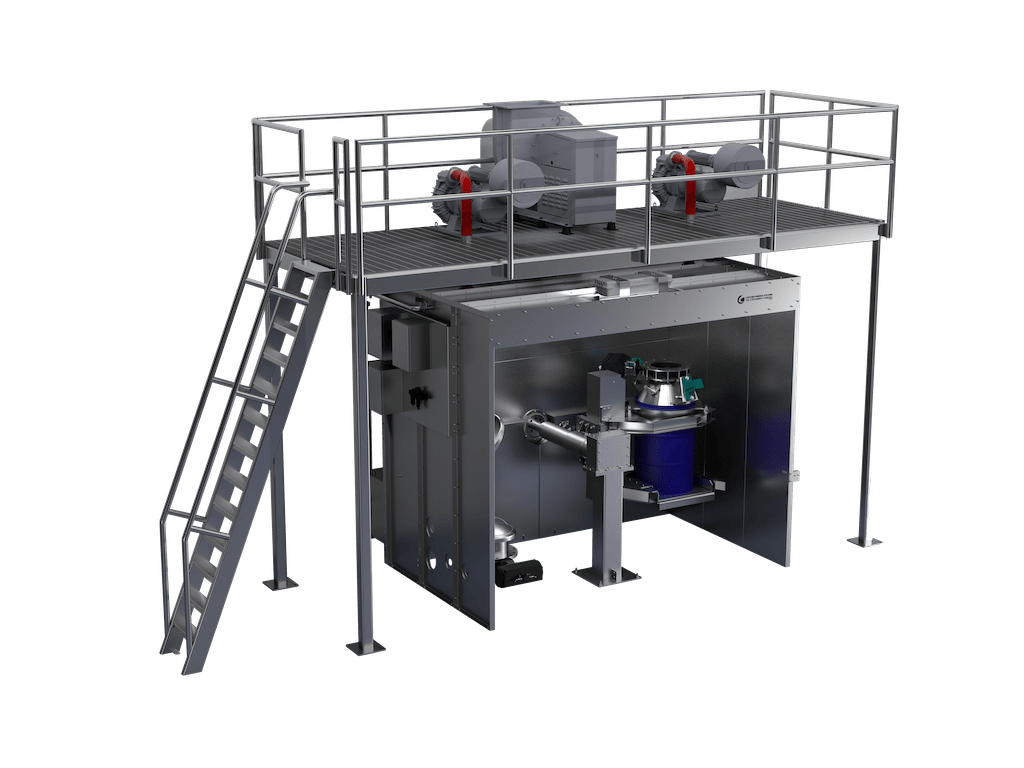

We specialize in providing tailored powder handling and containment system solutions.

Custom Powder Systems is a leading provider of solutions to transport, contain, blend, and process dry materials for additive, industrial, chemical, pharmaceutical, food, and nuclear manufacturing. Our Integrated Containment Systems division provides barrier technology of enhanced containment for dangerous components and/or barriers to protect product from outside contamination. We are experts in customizing products and design innovative solutions targeted to each of our clients unique needs.

The reason behind the name “Custom” Powder.

Our capabilities do not stop at stand-alone equipment;

we are a major provider of integrated “turn-key” custom systems.

The Art of Engineering is a podcast dedicated to telling the stories of incredible engineers who all share something in common: They’re women.

Host Denise McIntosh, CEO of Custom Powder Systems, knows firsthand the unique challenges women face in this industry and discusses them with her guests.

Articles and Resources

Accidental Invention: Saccharin

If you’ve ever looked through a collection of sweeteners for your coffee or tea, you’ve probably found several packets in various colors. But do you

Mothers of Invention: Alice H. Parker

If your home gets cold in the winter, you adjust the thermostat. However, in olden days, keeping a house warm involved laborious maintenance of wood

Historic Moments of Revolutionary Engineering: Samuel Morse Formulates Morse Code

Long before the wireless communication of today, electronic messages had to be sent in a unique language. Along with the creation of the telegraph came Morse Code – the key that unlocked new channels for human connection on a global scale.

Inventions Ahead of Their Time: French Fries

Is there anything better than biting into a fresh, salty, crispy french fry? Whether served alongside a burger or dipped into your milkshake, there’s no

Riata Center releases list of Cowboy100 honorees

Our beloved Chief Executive Officer, Denise McIntosh was named to list of upcoming honorees for the Riata Center for Innovation and Entrepreneurship to honor the

Accidental Invention: Safety Glass

Safety glass is commonly used in various applications where human safety is paramount. You’ll find it in vehicle windshields, architectural windows, shower enclosures, and computer