Containment Solutions IBC IBC Containers and Bins The original IBC Containers (Intermediate Bulk Container) was made from plywood in 1937 for the storage and handling...

Read MoreGas to Liquid Catalyst Dispensing System

Project Overview

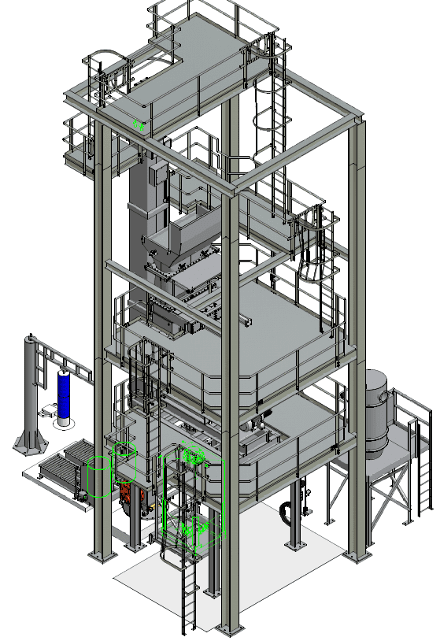

CPS designed, build, and installed a two-part system in accordance with client User Requirement Specification (URS).

System part 1 – Based on a Column Lift that receives steel drums containing solid catalyst raises them two at a time and tips them into a custom-developed Guillotine device. The Guillotine slices the catalyst into pieces small enough to enter the throat of a rotary mill. The milled product is received into a CP bin (IBC) for transport to part 2 of the system. A CPS modular mezzanine was provided to support all elements of the system as a free-standing solution. The aforementioned module was built, set up and tested in its entirety at CPS factory before disassembly, packing and shipment to Qatar.

System Part 2– A Column Lift elevate the IBC full of milled catalyst 65 ft to dock the IBC with the inlet of a melt tank. Once docked, the IBC valve opens to transfer product into the melt tank.

Additional Information

Related Products

Lifts and Manipulators

Lifts and Manipulators Column Lift Lifts Only the Best!—Clean electric drives with silky smooth precision actuation mechanisms. No leaky hydraulics or jerky pneumatic movement. All...

Read More