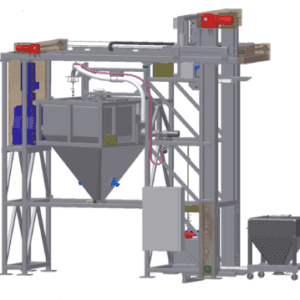

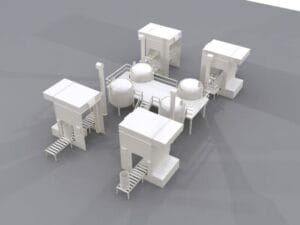

Helping Manufacturers Grow: Innovative Solutions for the Pharmaceutical Industry

With our expansive industry knowledge and engineering expertise, Custom Powder Systems provides groundbreaking solutions in the pharmaceutical industry that redefine how companies handle complex processes,