Blending Heavy Duty Single Pedestal IBC Blender Small, Laboratory, Medium and Large Scale Blending and Mixer Solutions The concept is simple. The same Intermediate Bulk...

Read More

Overview

A major nutritional supplement manufacturer needed greater efficacy and additional capacity in the production of its various vitamins and supplements.

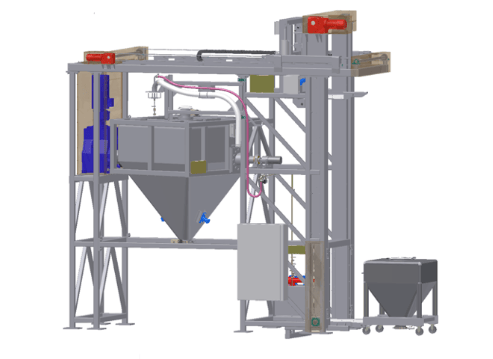

Custom Powder Systems (CPS) manufactured a 5000 Liter blender that fits and can be loaded and discharged within their limited manufacturing space and low ceiling heights. CPS 20° offset blender angle uses the blender sides as baffles and causes the material to cross flow as it is being tumbled.

Because of the weight of the blending vessel and its contents, CPS manufactured an innovated bottle in support cage design as a cost saving to their client.

Having total system responsibility, CPS integrated the bin lift, shuttle system and clean-in-place system with a fully automated user-friendly recipe driven control system.

The nutritional supplement manufacturer quickly realized the positive impact and contribution the blending system is having on their present and future production needs

Additional Information

Related Products

Lifts and Manipulators

Lifts and Manipulators Column Lift Lifts Only the Best!—Clean electric drives with silky smooth precision actuation mechanisms. No leaky hydraulics or jerky pneumatic movement. All...

Read More