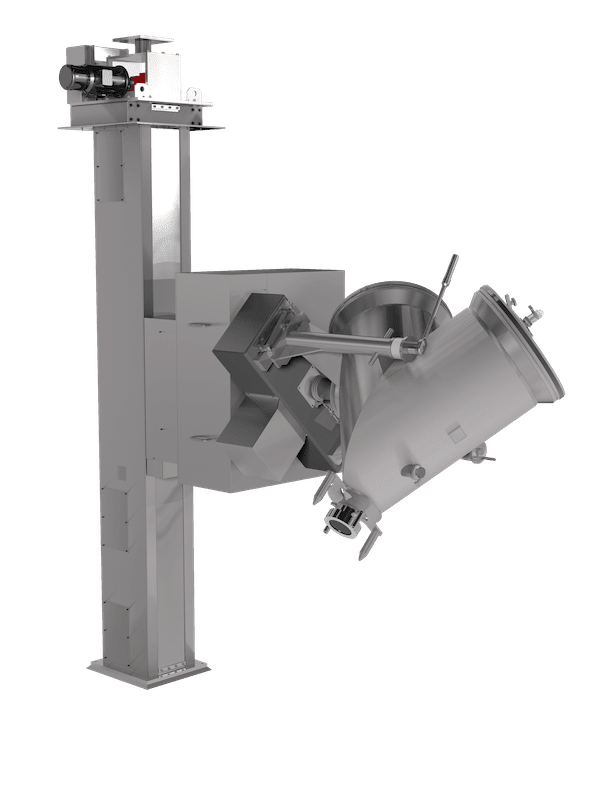

Pyrophoric Material Dispensing System Pedestal Blender Column Blender Blending Comparison Pedestal Blender (PB) vs. Column Blender (CB) A. Versatility – Column Blender Best A pedestal...

Read More

Small, Laboratory, Medium and

Large Scale Blending and Mixer Solutions

The concept is simple. The same Intermediate Bulk Container (IBC) that is used for shipping and storage is also used for blending or mixing.

• Total product containment

• No cleaning is required on the blender. The IBC is cleaned off-line

• No cross-contamination

• Fast blending

• Less ingredient segregation

• Increased process flexibility

• Often referred to as IBC Bin Blender or IBC Tumble Blender

Blending Options

Interested in product information?

Here are download versions of product specifications and information.

How It Works

Tumble blending is a dual-action blending principle. The first blending action is produced by a wave as the material is tumbled. This wave (or shear plane) occurs in the top ¼ of the product load. The second blending action is produced by the cradle orientation. The IBC is held in the blender at an angle to position the IBC horizontal center of gravity 20° from the Blender tumbling centerline. This geometry places the IBC shell walls at cross flow producing angles to the blend axis, acting as baffles as the product is tumbled.

IBC Blender Benefits

Dry powder blending is simplified when you use IBC blending that reduces blend times and requires no between batch cleanups. Since products contact only the IBC, you benefit from total product containment, immediate product changeover and zero blender cleaning. You also eliminate airborne and cross-contamination, product segregation and spillage risks.

Overview of IBC Blending Benefits:

- Total product containment

- Reduced risk of segregation

- No down time for blender cleaning

- Increased process flexibility

- Conducive to automation

- Reduced blend times compared to other blender types

Key Features

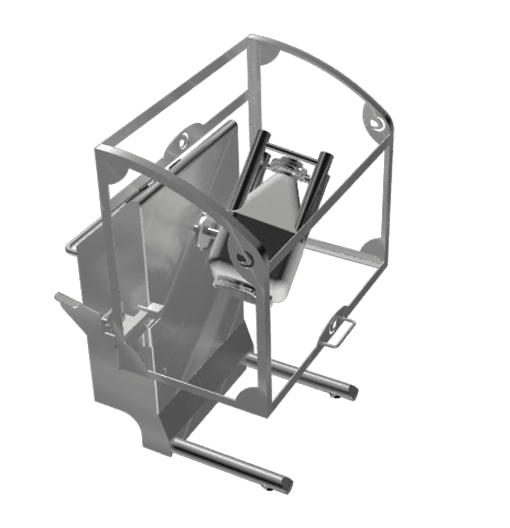

- Offsetting the IBC in the blender frame between 20 and 30 degrees causes the powder to change the direction of flow 6 times for every rotation improving both the blending time and consistency.

- No blender clean up required between various recipes

- Low idle time between batches provides increased production

- Pre-batched bins of products quickly loaded into the blender is a great benefit.

The reason behind the name “Custom” Powder.

Our capabilities do not stop at stand-alone equipment;

we are a major provider of integrated “turn-key” custom systems.

Additional Information

Loading, Blending and Mixing System

Loading, Blending and Mixing System Overview A major nutritional supplement manufacturer needed greater efficacy and additional capacity in the production of its various vitamins and...

Read MoreBenefits of IBC (Bin) Containment Blending

Aseptic Powder Dispensing and Blending System Overview The concept is simple. The same Intermediate Bulk Container (IBC) that is used for shipping and storage is...

Read MoreThe Truth About Blending Baffles

Aseptic Powder Dispensing and Blending System Blending baffles are one of the most misunderstood principles in IBC Tumble Blending. The purpose of this paper is...

Read MoreTip Speed Blending

Tip Speed Blending Tip Speed – Establishing Optimal Blending Speed Tip speed (angular velocity) is a constant that can be used to establish an...

Read MoreContainment Tool Box

Pyrophoric Material Dispensing System Enhance product safety and prevent release during transfer operations. Perfect for professionals looking for a containment tool box. The potency of...

Read MoreEZ Down Systems

Aseptic Powder Dispensing and Blending System Custom Powder Systems announces dramatic yield increase through use of anti-segregation technologies. A unique solution improves yields from less...

Read MoreAseptic Powder Dispensing and Blending System

Pyrophoric Material Dispensing System Download Case Study Information Fortune 100 Pharmaceutical Corporation Sterile Powder Dispense and Blending Project Project Overview – CPS prepared a system...

Read More