Containment Solutions IBC IBC Containers and Bins The original IBC Containers (Intermediate Bulk Container) was made from plywood in 1937 for the storage and handling...

Read MoreFortune 100 Pharmaceutical Corporation

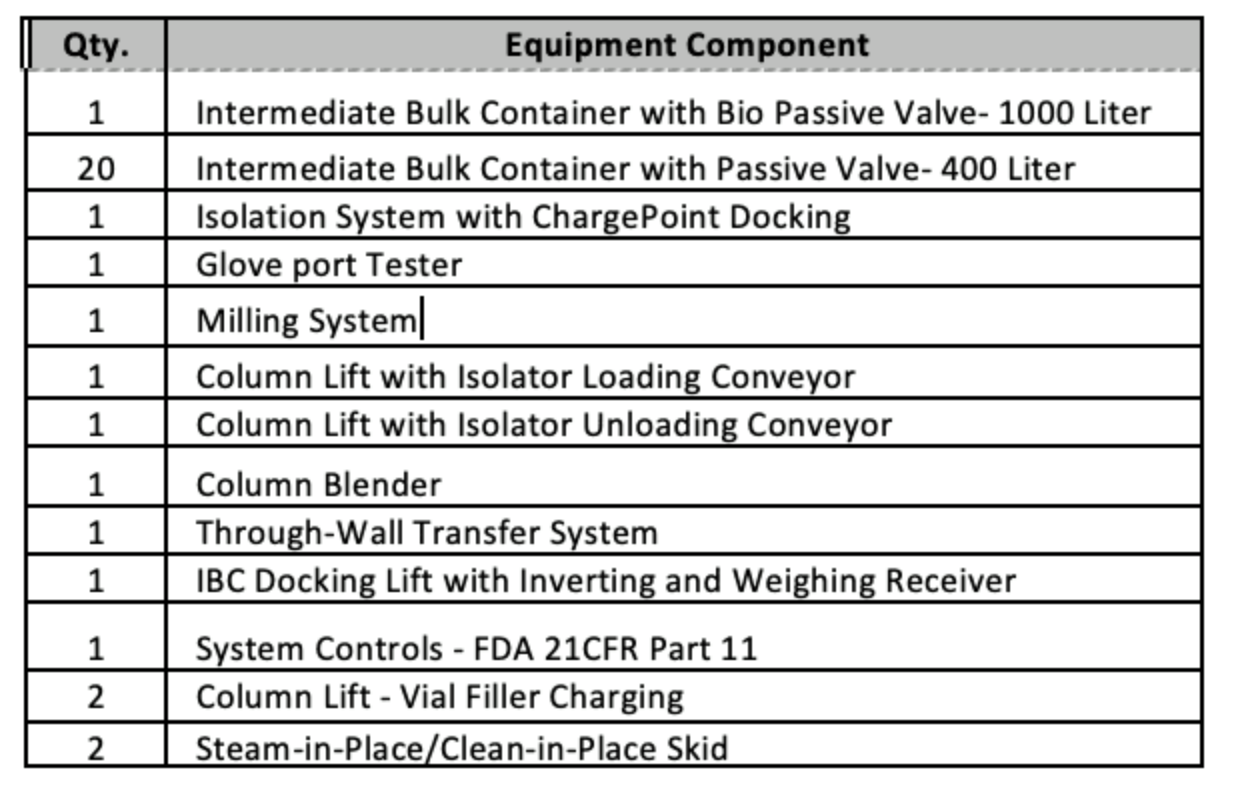

Sterile Powder Dispense and Blending Project

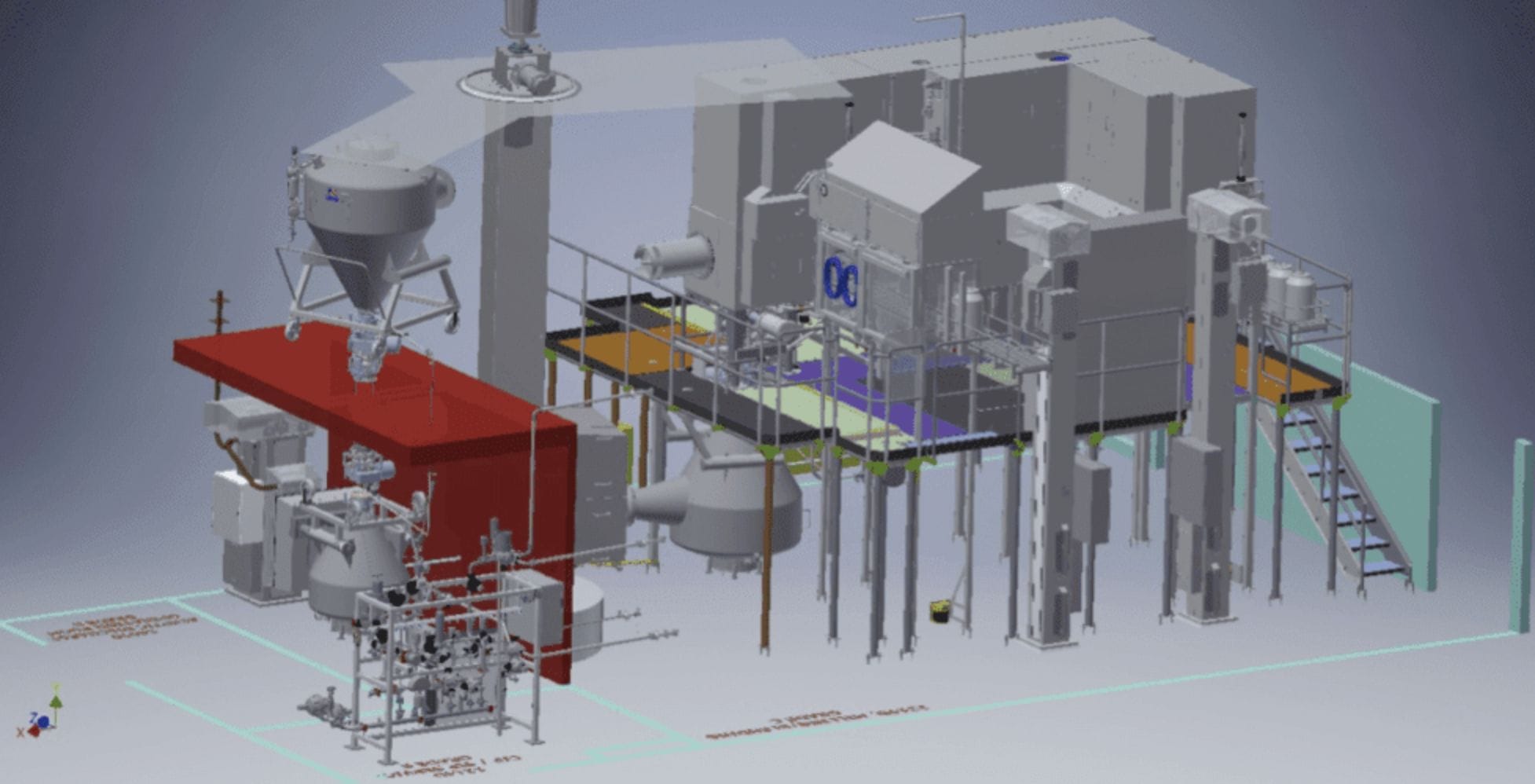

Project Overview – CPS prepared a system specification and subsequent proposal through a series of eight interviews with the client for a fully automated system to dispense sterile antibiotic powders from aluminum shipping cans, mill, blend and feed these powders into vial filling equipment. The system includes VHP system a to bio-decontaminate the system to and aluminum shipping cans prior to dispensing. The cans are automatically de-lidded by a sterile duty robot located inside the isolator. The system operates through a SCADA system compliant with FDA 21CFR Part 11 for electronic signatures and records. Performance goals of the system are two batches per day of 22 to 26 cans of product per batch with operator intervention only to load and unload cans from the system and to transport IBC of the processed product to the respective vial filler.

Aseptic Powder Dispensing and Blending System

Additional Information

Related Products

Aseptic Isolator

Isolators Aseptic Isolator Aseptic Isolator Basic Features The Aseptic Isolator is designed to the challenges and market requirements for low OEL containment systems in Pharmaceutical,...

Read MoreLifts and Manipulators

Lifts and Manipulators Column Lift Lifts Only the Best!—Clean electric drives with silky smooth precision actuation mechanisms. No leaky hydraulics or jerky pneumatic movement. All...

Read More