Plenum Ventilation CLeanroom plenum Ventilation Plenum ventilation is a self-contained unidirectional flow module, designed to meet requirements for cleanliness levels of ISO Class 5 or...

Read More

Enhance product safety and prevent release during transfer operations. Perfect for professionals looking for a containment tool box.

The potency of APIs (Active Pharmaceutical Ingredients) in OSD (Oral Solids Dosage) formulations has been increasing for years and the number of potent compounds only continues to grow. This necessitates additional provisions to protect personnel from exposure to these chemicals.

The risk or exposure or containment of a potent compound exists in the technology used for product transfers.It is quite simple to assure containment once the product is in a “box” but the process of putting in the box or removing is where the risk/challenge lies.

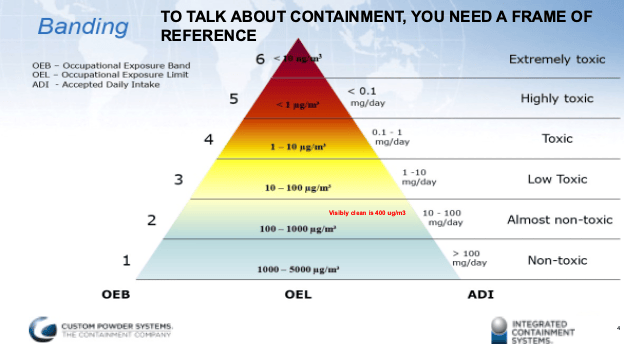

There are many ways and units used to express the containment level need of a system. This banding diagram provided here gives a convenient cross reference across different containment level terminology. Setting the containment level is the first important first step to communicate a measurable threshold for your vendor to achieve. This paired with a well thought out URS gives the basis for further discussion with your vendor partner.

We have a toolbox of 13 principal containment devices we use in our OSD system designs; 10 being active barriers that prevent product release and three basic devices that capture the product release during a transfer operation. As vendor we must achieve the clearest possible understanding of a clients need, intended use and operator-centric methods to select the best tool or combination of tools assure a robust solution the projects containment levels. With this we can prepare a solution that protects the people within your budget and timeframe.

Additional Information

Related Products

Downflow Booth

Downflow Booth DOWNFLOW BOOTHS ARE USED FOR MULTIPLE BULK HANDLING APPLICATIONS. THESE UNITS ARE USED TO UPGRADE FACILITIES OR IN NEW FACILITY CONSTRUCTION TO REDUCE...

Read MoreDrum Conditioning

Drum Conditioning WHAT’S THE SAFEST AND EASIEST WAY TO BREAK UP HARDEN PRODUCT IN YOUR DRUMS OR BOXES? THE DRUM MASSAGER! Enter the CPS Drum...

Read MoreContainment/IBC/Bins/Totes

Containment Solutions IBC IBC Containers and Bins The original IBC Containers (Intermediate Bulk Container) was made from plywood in 1937 for the storage and handling...

Read MoreAseptic Isolator

Isolators Aseptic Isolator Aseptic Isolator Basic Features The Aseptic Isolator is designed to the challenges and market requirements for low OEL containment systems in Pharmaceutical,...

Read MoreLyophilizer Cart

Lyophilizer Cart Lyo Cart Lyo Transfer Cart The Portable Lyo Transfer Cart is a self-contained, battery powered enclosure designed to transport products through uncontrolled spaces...

Read MoreRABS (Rigid Access Barrier System)

RABS (Restricted Access Barrier System) For Aseptic Processing & Fill-Finish Operations Restricted Access Barrier Systems (RABS) provide an advanced solution for pharmaceutical aseptic processing, sterile...

Read MoreAnti-Segregation Solutions

The EZ-Down system provides gentle and controlled mass flow during gravity material transfers without damage, degradation, or segregation of the product.

Read MoreCleaning Systems

Cleaning Solutions IBC Wash Station Automating the cleaning process CPS provides solutions to automate production equipment cleaning and assure/validate the repeatability of results that is...

Read MoreLifts and Manipulators

Lifts and Manipulators Column Lift Lifts Only the Best!—Clean electric drives with silky smooth precision actuation mechanisms. No leaky hydraulics or jerky pneumatic movement. All...

Read More