Blending Heavy Duty Single Pedestal IBC Blender Small, Laboratory, Medium and Large Scale Blending and Mixer Solutions The concept is simple. The same Intermediate Bulk...

Read More

Tip Speed – Establishing Optimal Blending Speed

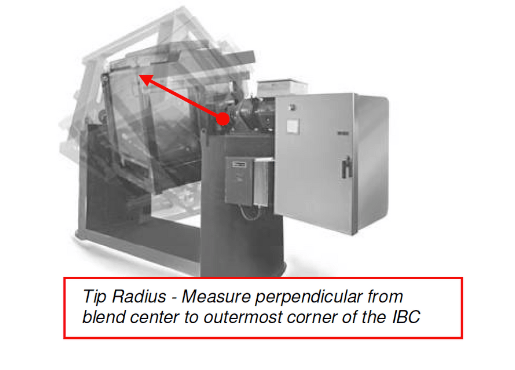

Tip speed (angular velocity) is a constant that can be used to establish an

initial blending speed for a given bin geometry. The blender speed may

need to be adjusted upon further testing but is a good starting point. The tip

radius is the distance perpendicular to the blender rotational center

measured to the furthest top bin corner.

Formula

TS = 2100 in/min tip speed constant

TR = Tip Radius (in inches)

RPM = blender rotational speed (in revolutions per minute)

PI = 3.1415

RPM = TS/(PI x TR x 2)

These speed values are approximate based on average density materials 40#/ft3, good flow properties, and particle sizes within 40% of each other. This formula is not relevant for IBC capacities less than 200 liters.

Adjusting for less than ideal product

Product density influence on blend speed

*Increase blend speed for denser products

*Decrease blend speed for lighter products that are prone to aeration.

Product flow properties influence on blend speed

*Decrease blend speed for products with poor flow properties

*Increase blend speed for products with excellent flow properties

Particle size influence on blend speed

Particle size variation over 40% – blend speed change has little effect. Draw blend samples much morefrequently (at least every minute of blend time) during initial blend testing because batches with large particle size variation can de-blend if run too long.