Plenum Ventilation CLeanroom plenum Ventilation Plenum ventilation is a self-contained unidirectional flow module, designed to meet requirements for cleanliness levels of ISO Class 5 or...

Read More

Containment Solution: The DownFlow Booth

The potency of APIs (Active Pharmaceutical Ingredients) in OSD (Oral Solids Dosage) formulations has been increasing for years and the number of potent compounds only continues to grow. This necessitates additional provisions to protect personnel from exposure to these chemicals.

The risk or exposure or containment of a potent compound exists in the technology used for product transfers.It is quite simple to assure containment once the product is in a “box” but the process of putting in the box or removing is where the risk/challenge lies.

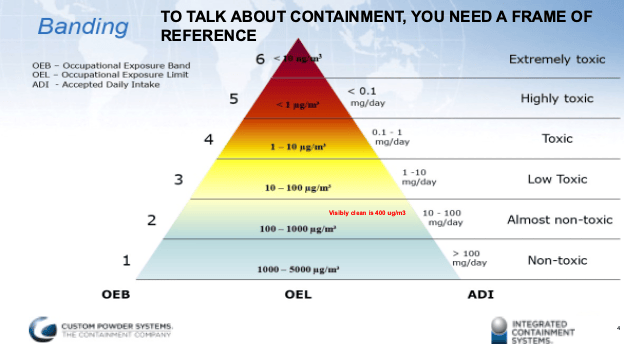

There are many ways and units used to express the containment level need of a system. This banding diagram provided here gives a convenient cross reference across different containment level terminology. Setting the containment level is the first important first step to communicate a measurable threshold for your vendor to achieve. This paired with a well thought out URS gives the basis for further discussion with your vendor partner.

We have a toolbox of 13 principal containment devices we use in our OSD system designs; 10 being active barriers that prevent product release and three basic devices that capture the product release during a transfer operation. As vendor we must achieve the clearest possible understanding of a clients need, intended use and operator-centric methods to select the best tool or combination of tools assure a robust solution the projects containment levels. With this we can prepare a solution that protects the people within your budget and timeframe.

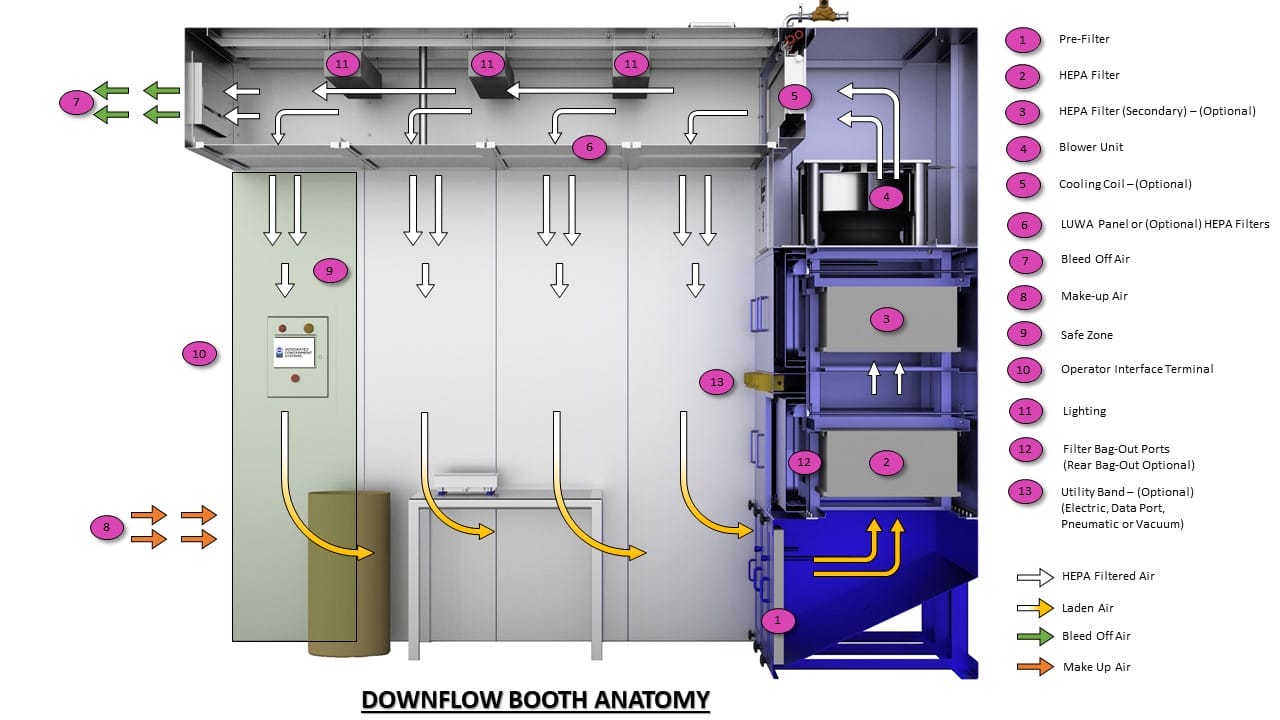

The Downflow both is our general-purpose containment device for open product transfers that serves to protect workers from product inhalation when working inside the booth. The Downflow both created a downward air flow path to prevent product from migrating towards into an operator’s breathing zone. The secondary function of the Downflow booth is to contain product released inside from migrating into the corridors and other areas of the facility. The booth is a self-contained system with blower, filters and controls to supply a safe working environment (band 2; 100 µg/m³) for powdered APIs and Excipients, while sampling, weighing and dispensing. The booth is supplied with lights, alarms, monitors and temperature control. The ceiling plenum is designed with HEPA filters and stainless-steel diffuser panels (90 fpm airflow) and supplied with lights with a 5-15% bleed air discharge. These filters are DOP testable units for certification. Pre-filters are provided in the return grilles.

Additional Information

Related Products

Downflow Booth

Downflow Booth DOWNFLOW BOOTHS ARE USED FOR MULTIPLE BULK HANDLING APPLICATIONS. THESE UNITS ARE USED TO UPGRADE FACILITIES OR IN NEW FACILITY CONSTRUCTION TO REDUCE...

Read More