Services

While we specialize in building custom machines,

the question becomes not only:

What can we make, but what can we do?

Engineering & Design

When you need an innovative solution, our team spends the necessary time with you specifically dedicated to uncovering your unique goals and challenges. Whether it’s constructing a brand new machine or just adding accessory parts to an existing one, we’ve got you covered.

The process is simple: you bring us your issue, and our panel of experts will either custom design and build a product that fits your exact specifications, or we will work with your existing equipment and infrastructure and make modifications accordingly.

We Provide Solutions For:

- Compatibility

- Containment

- Contamination

- Discharge Spillage

- Extracting Hardened Materials from Drums

- Functionality

- Lifting Issues

- Low Yields

- Segregation of Blended Materials

Technical Services

Thanks to our customer support network, you’ll never be uncomfortable or uncertain about any aspect of your CPS system. We don’t just send you a machine and hope you figure it out. We continue to be available long after you receive your product so your satisfaction with our service is guaranteed.

We Answer Inquires Like:

"What's the next step once my new equipment is installed?"

“How do I operate my new machine?”

“Where can I find replacement parts?”

“When should I schedule system maintenance?”

Replacement Parts

Our replacement parts division excels in fixing what’s broken… No matter who made it.

When one machine stops working, everything stops working. And when everything stops working, everyone looks to you for a solution. But the issue is not always easy to detect.

That’s where we come in.

Custom Powder Systems® is always here to find the parts that help you fix your production problem. And when you find the solution that fixes your production problem, you’re the hero.

Maintenance

Sometimes, machines need fixing – that’s just how technology works. We can service, repair, and upgrade machines we built, as well as those from other manufacturers, even if that manufacturer is no longer in operation.

When you reach out, we will: gather information, do some research, consult with our technical team, and get back to you as quickly as possible. You’ll then be able to discuss your issue directly with a knowledgeable service technician, engineer, or programmer. If your machine came from us, these will be the people who had a hand in building your system, so they will know it better than anyone else.

Our Maintenance Services Include:

Annual Service/Maintenance Contracts

Equipment Inspection

Equipment Upgrade and Rebuilds

Evaluation of Your Preventative Maintenance Program for Compliance with OEM Specifications/Requirements

Preventative Maintenance

Repair and Service

Replacement Parts

Spare Parts

Training

Equipment Testing

We don’t guess. We test… Multiple times.

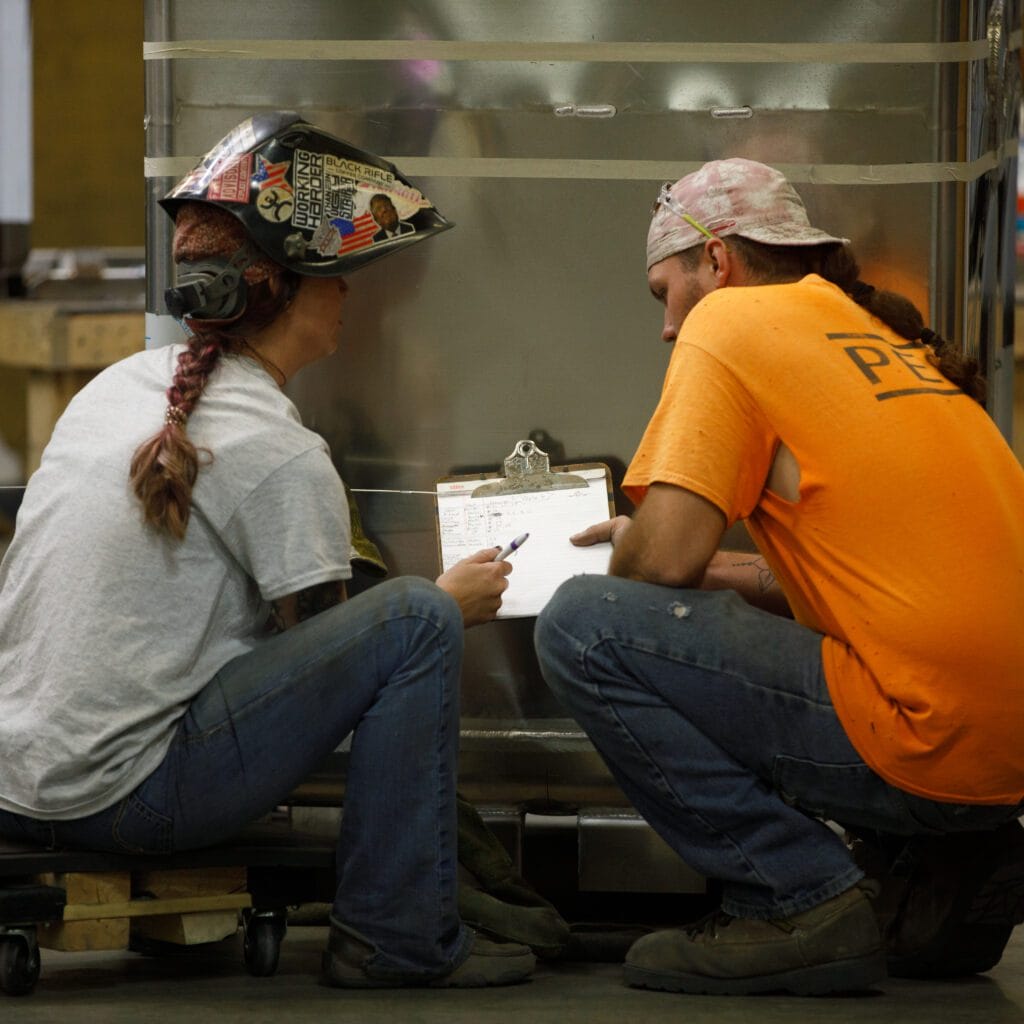

Once your piece of equipment is mechanically ready and wired in our shop, we take over the machine, check inputs and outputs, make adjustments if needed, and subject it to our exhaustive testing process. In this phase, bugs are revealed, researched, and rectified before the machines are shipped to your facility.

When it is delivered, our Technical Services team will be on-site to supervise and assist with assembly, wiring, and establishing network connectivity for your equipment, as well as optionally assisting with the first blend to ensure it comes out correctly. We then perform a site acceptance test to confirm the equipment is bolted down, all parts are together, and all devices are adjusted and running perfectly.

Things We Test For:

- Does the automatic mode run?

- Does the manual mode run?

- Do the lights come on?

- Does it dock?

- Is the machine doing everything it was designed to do?

Finally, we provide you with a detailed document describing the operation of your equipment.

When you work with us, you will not only get quality, custom-built, specialized equipment but also the knowledge and confidence to operate it properly.

Documentation & Validation

As a project takes shape, we incrementally review key documents during the design and construction process, keeping our lines of communication open and preventing problematic and costly modifications in the final stages. We pay close attention to regulatory changes, and our approach to validation is constantly evolving.

Custom Powder Systems Installation Qualification (IQ) and Operational Qualification (OQ) documentation and validation packages provide recorded evidence that our systems are built and commissioned in accordance with user requirements (URS), functional specifications (FS), and FDA and cGMP standards.