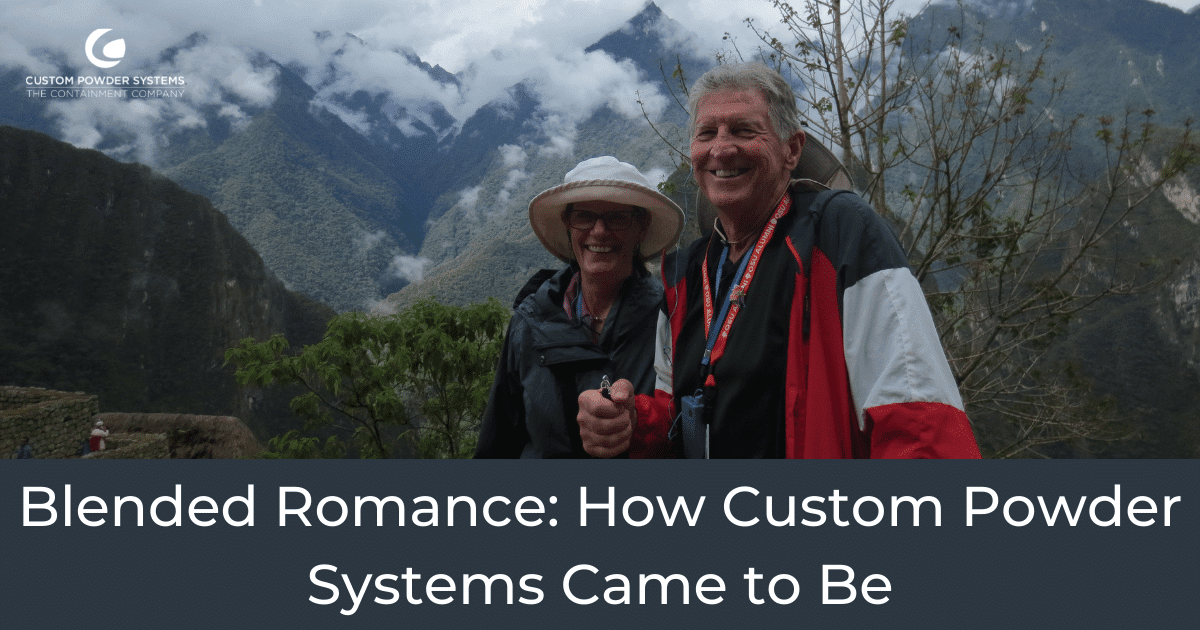

“I don’t know how many times my boss introduced us… He really only needed to introduce us once,” recalls Denise on meeting Dale “Mac” McIntosh. The two had been working in the plant food industry and, if opposites do attract, Denise and Mac soon figured out how to blend their different personalities.

“She’s my alter-ego,” says Mac. “She’s a logical, deep-thinker, and I’m more of a visionary ‘let’s get it done’ type.” Something that may have caused a clash in other couples worked as a catalyst to bring these two together. One could see the big picture while the other worked out the details. They knew they had a “big picture” future together, but nobody else did yet.

Is Denise There?

Mac and Denise’s skills extend past their business knowledge. If you need something to be kept secret, they’re your people. They successfully spent seven years quitely living together until one morning the phone rang:

“Hello?” said Mac, answering Denise’s phone.

“Is Denise there?” replied the voice on the other end.

“Not right now.”

“Mac!?!”

Mac then explained to their mutual friend that they had been “meaning” to tell him the two were a couple and today, he supposed, was as good a day as any. “Oh, and by the way, we’re getting married in six months.”

Around this time, Mac and two of his co-workers, Scott Heffern and Bob Luebbe, had been discussing the idea of going into business together. As they sat around the table, Denise finally jumped in and said “I want in.” This took Mac by surprise, as the idea of having his life-partner also be his business partner hadn’t crossed his mind.

But to Denise, it made perfect sense. “My theory is: I’ve worked with crazy people over the years, and there comes a point where you have to decide ‘am I going to work with known crazy, or unknown crazy?’ and at least I know these guys. And I have experience there.”

The Best Place We’ve Ever Worked

Nobody had yet taken the idea of bulk material handling and systemized it. The pieces were all out there, but no company had yet excelled at bringing it all together. There needed to be a turn-key solution for the powder handling industry, whether it was food or pharmaceutical. They quickly saw there was an opportunity to develop the equipment and systems to take a project from raw materials to a packaged product. But their new company needed one more thing…

“The overriding principle,” explains Mac, “was ‘let’s make this a place where we can all participate and really enjoy working, enjoy coming to work every day, and do something special for not only the employees, but provide something unique to the marketplace.’”

Denise adds, “Our whole premise was to start a company that was A) the best place we’d ever worked, and B) hopefully make it the best place our employees have ever worked.”

Relationships Build Businesses

While the story began as the spark of a relationship between Denise and Mac, the business continues to be successful because of their relationships with customers. Over 80% of the companies they do business with today are repeat customers. “As our company moves into its next phase,” adds Mac, “Denise and I couldn’t be happier that Bob Luebbe is at the helm as president. He was there at the beginning of the relationships with our clients, and I know in my heart those clients will be treated exactly how we would treat them.”

Strong relationships have also accounted for happy, loyal employees. Some have, occasionally, gone on to other opportunities, but Denise and Mac let them know the door will always be open for them to come back. One “temporary” former employee was back within forty-eight hours. That speaks to the kind of care the McIntosh’s take with their employees and shows the fulfillment of their goal to make Custom Powder Systems “the best place anybody has ever worked.”

Sixteen Years and More to Come

Custom Powder Systems continues to be a resource for any industry dealing in bulk powder and containment, from pharmaceutical companies like Pfizer to food production like Pepperidge Farms.

As the industry continues to expand, so do the skills of our team. You’ll find our solutions in pharmaceutical plants in China and in the oil fields of Qatar. No matter what shape they take, our goal is to solve interesting problems and help make companies more efficient. Everytime you’re faced with a challenge is another chance for us to excel at what we do best.

We’d love to be a part of your story… and have you as a part of ours. What can we invent for you today?

_________________________________________________________________________

To hear more about the art of engineering, sign up for our newsletter.