We believe there’s no reason for new DSCDA serialization rules to slow you down. There’s always an elegant solution to the most complex situations.

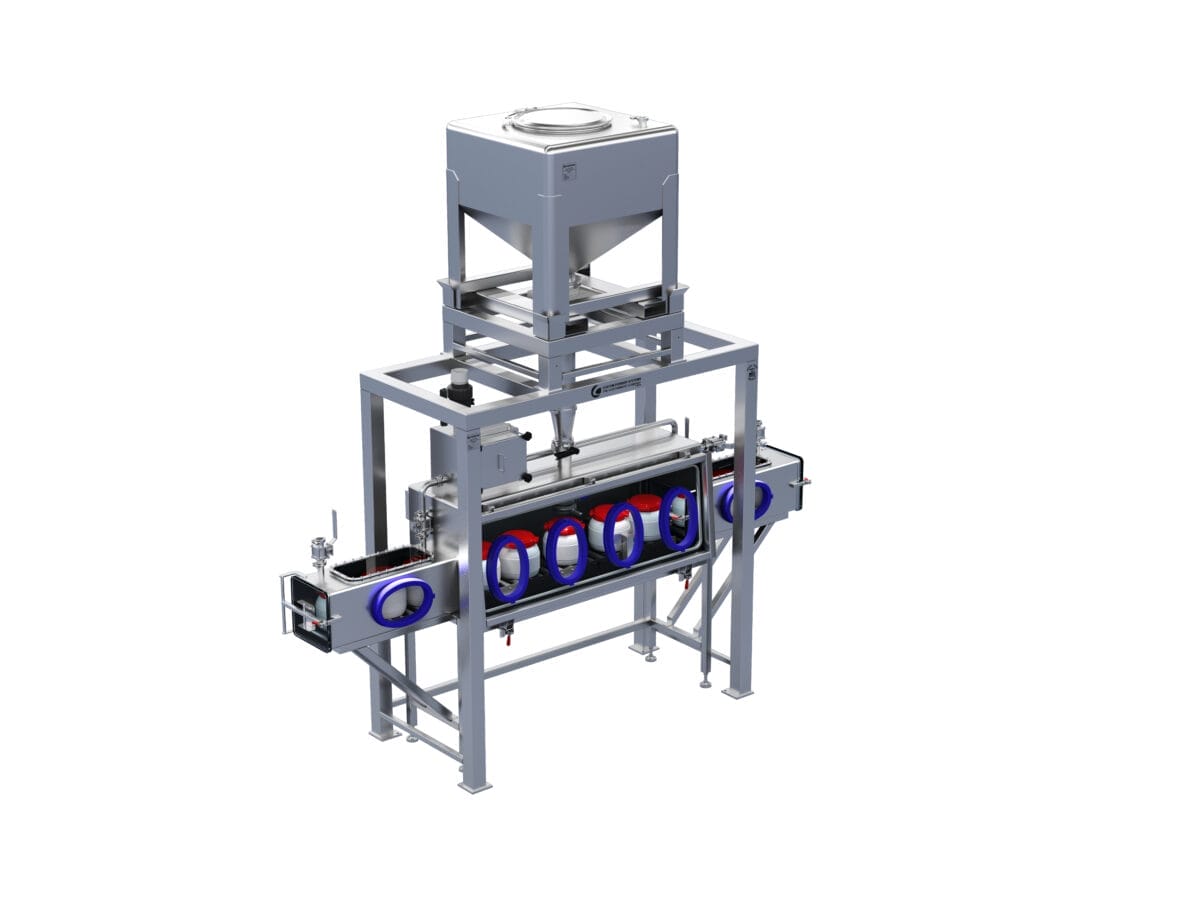

With our Serialization Aggregation Workstation, or SAW, you will double your output compared to manual serialization stations. SAW has a smaller physical footprint, helps eliminate errors, and frees up your staff to handle more important tasks. And that all happens at almost half the price.

The new serialization rules have added costs in labor and error correction. Each new step added to the process is yet another opportunity for a mistake to be made. When creating the Serialization Aggregation Workstation, Custom Powder Systems and RemTech solved multiple problems all at once.

Keep Up, Speed Up, and never Slip Up

The new Serialization Aggregation Workstation allows you to:

1. KEEP UP with serialization aggregation regulations

2. SPEED UP packaging by eliminating bottlenecks

3. VIRTUALLY ELIMINATE ANY SLIP UPS

Our modular design means it takes up less space than older systems.

Intuitive automation means fewer hands handling packages. That reduces mistakes.

All while increasing throughput from 1 to 2 cases per minute…to an impressive 10 cases per minute – nearly a 500% jump!

The Serialization Aggregation Workstation scans and then immediately seals.

This virtually eliminates mistakes. And if a scan does detect a problem, it’s immediately taken out of the line.

SAW was built with the serialization aggregation mandates in mind.

You will be fully compliant ahead of schedule.

Because SAW reduces the number of people needed to handle packaging, your company is able to reallocate staff to more important projects, without increasing labor costs.

More efficient… in a smaller space… costing you a lot less money… and error-free.

The Serialization Aggregation Workstation

Scan it. Close It. Tape it. Ship it.