“…and in an instant, everything changes.”

Have you heard that a few times this year? 2020 will be remembered for many things, but the common thread is change.

And if we’re not talking about change, we’re talking about health and healthcare. Future needs and regulations can pop up at any time…and that makes for the (not so) perfect combination of “change” and “healthcare.”

Our feeling on change: Bring it on.

We get a quiet smile each time we pull off something others couldn’t do. We’re not the bragging type. But when it comes to tomorrow’s challenges, Custom Powder Systems loves beating the odds.

The pharma industry continues to evolve at a rapid pace, and our creations stay a step ahead.

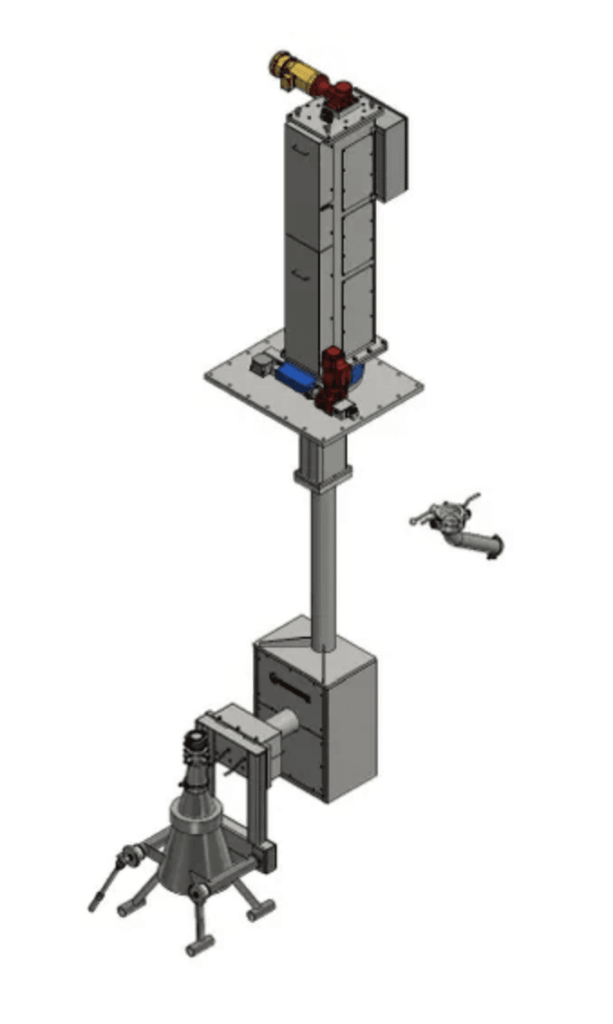

Inverted Lift

The problem was a column lift in a less-than-ideal space. It needed to be out of the way when not in use, but permanently in place to accommodate precision connections. Every other engineer said it couldn’t be done. But Custom Powder turned the whole idea on its head.

If a lift can go up and down…it can also go down and up. In order to help a customer save important floor space while maintaining the needed precision of the lift, our engineers found a way to mount it to the ceiling!

This involved some masterful logistics in order to account for all the wires, conduit, and ventilation that lives in a ceiling. The result seemed to defy gravity. It also solved a huge problem for a busy company.

Virtual F.A.T.

Nobody is sure when you’ll get to easily hop on a plane and put a new piece of equipment again. The Factory Acceptance Test is one of the most crucial last steps before your equipment is put into place, but travel limitations have made them nearly impossible.

Ah! There’s that word again… “impossible.” Knowing that you needed to see your new equipment in action, we created a Virtual F.A.T. You’ll work with our engineers to make sure everything works right, and you can even take virtual control to see how it works for yourself.

It’s important that we do everything we can to ensure the equipment performs as you want it to. And while nothing beats a friendly face-to-face and hands-on F.A.T., our Virtual F.A.T. has been shown to save time and prevent future errors.

Serialization Aggregation Workstation

S.A.W. is a marvelous combination of modern-tech and Henry Ford-like assembly. Matching labels on bottles with labels on boxes with labels on pallets got to the point of becoming mind-numbing. SAW is the way the pharma industry can scan, close, tape, and ship virtually error-free.

- Intuitive automation means fewer hands involved in the process, breaking open bottlenecks.

- Scanning that’s instantly cross-checked means the right product goes into the right box.

If all SAW did were those two things, it would be a huge improvement in your process. But SAW is built to keep up with the Drug Supply Chain Security Act. As DSCSA is being phased in, your procedures will be ready and compliant.

The modular design of SAW means it can fit in many plants, with a smaller footprint than your current assembly.

And the speed and precision have been shown to take the packaging of 1 to 2 boxes per minute up to a rockin’ 10 boxes per minute. How’s that for efficiency?!

Together, this saves you time, space, and lets you put important personnel in new roles.

Looking to Tomorrow

If the future seems full of twists and you’re not sure how you’re going to handle it all, give us a therapeutic phone call. We love working with companies who are forging forward into tomorrow ready to beat the challenges that are coming.

You can reach us through our contact form, or call 417-868-8002*.

*We’ve also been known to Zoom, Meet, and Team!