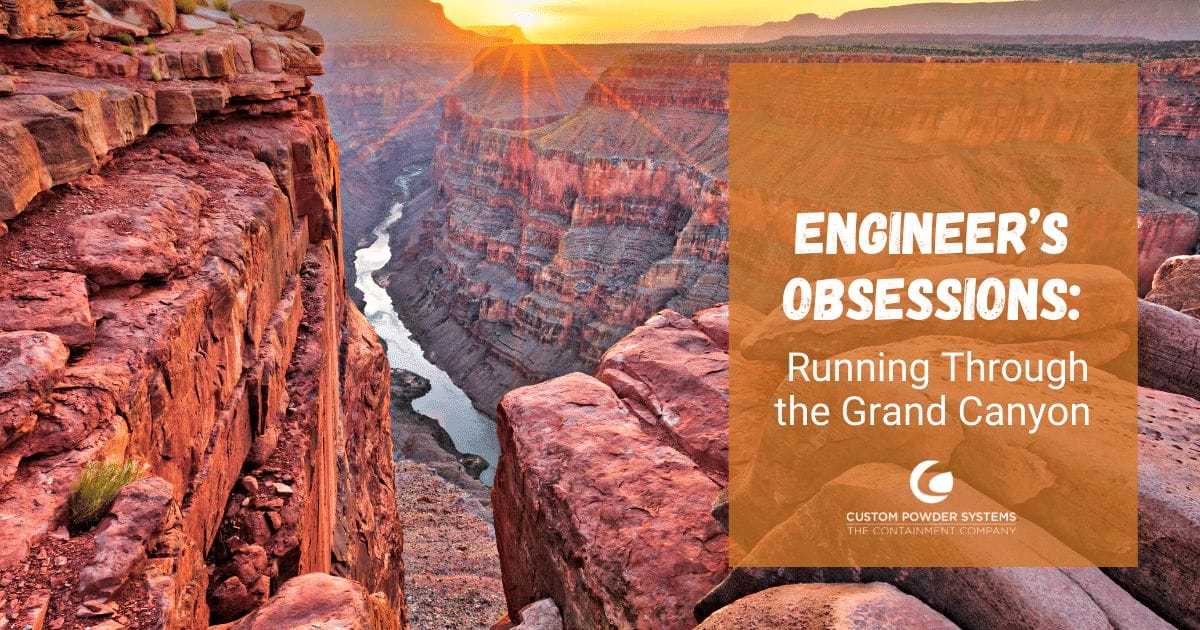

Dean Casady, Technical Services Director at Custom Powder, has been a runner for 45 years. Recently, he decided to take on one of the most rigorous runs on earth: A run into the Grand Canyon, traveling from rim to rim to rim, also known as R2R2R.

“It’s seven miles to the bottom, nine miles across, then six miles up to the north rim,” says Dean. Then you have to get back. “We started at 4:15 in the morning and finished at 11:30 at night.”

Because of the tremendous shifts in elevation, temperatures vary wildly. The terrain goes from mountain, to desert, to forest, and everything in between. Dean says after the first five miles when the sun begins to rise, you realize the enormity of the task ahead. “We’ve traveled five miles, and we still haven’t gotten to the bottom. We got to this outlook, and we could finally see the entirety of the river from left to right. It was like we were looking at another canyon inside of this canyon.”

No Cheering Squads or Water Stations Here

The National Park Service doesn’t allow organized runs or competitive races in the canyon. Because of this, runners need to account for everything they might need.

“You burn a lot of calories, so I had lots of energy food. A great deal of water, too. I probably consumed five litres of water.” In case the water he packed wasn’t sufficient, Dean brought along water filters and purifiers.

The route is one for serious hikers, and through the entire journey Dean and his two companions only encountered about a dozen other people. This doesn’t leave many options if something goes wrong. “We had contingency plans and cutoff points where we needed to be at certain times, but any rescue would be either via mule or helicopter. And it’s very expensive.”

Training for All Terrains

Getting ready for a run this extreme has its own challenges. There’s only one Grand Canyon, and finding similar terrain isn’t very easy. “We do a lot of back-to-back runs, which is a 15 to 20 mile run on back-to-back days. We go about 20 miles south of Springfield, Missouri to the Ozarks, or down to the Buffalo River in Arkansas. There’s some rugged terrain there.”

No matter how long one trains, Dean claims you can’t prepare for absolutely everything the Grand Canyon holds. “You’re never as ready as you want to be,” he explains. “I thought, ‘maybe I’m biting off more than I can chew.’ But I started talking to other people interested in doing the same thing, and he convinced me we could do it. I started training, and then we did it.”

Planning and Commitment

As with engineering, a run like the R2R2R requires both planning and commitment. “They both require very hard work. I don’t do either of them casually. If you’re going to do something like the Grand Canyon, Pikes Peak, or Boston Marathon, you don’t just show up. It requires a lot of commitment,” Dean says.

His career resume includes being an Automation Engineer, Automation Director, and our Technical Services Director here at Custom Powder Systems. Like our other engineers, Dean Casady’s outside passions demonstrate a determination to see a challenge through to the end.

When he’s on break from advancing his engineering skills, Pikes Peak is next on Dean’s big adventure list. Whether it’s a journey through the Grand Canyon or a solution for our customers, he knows there’s always a way to reach the destination.

We have a team standing by ready to take on the challenge of your next project. What can we build for you?

To hear more about the art of engineering, sign up for our newsletter.