Whether your Intermediate Bulk Containers need modifications for a new process idea or repairs from a little run-in with a forklift, we at CPS are happy to fix them up for you. While we do specialize in building custom machines, there are also some significant benefits to choosing to refurbish your old bins instead of buying new.

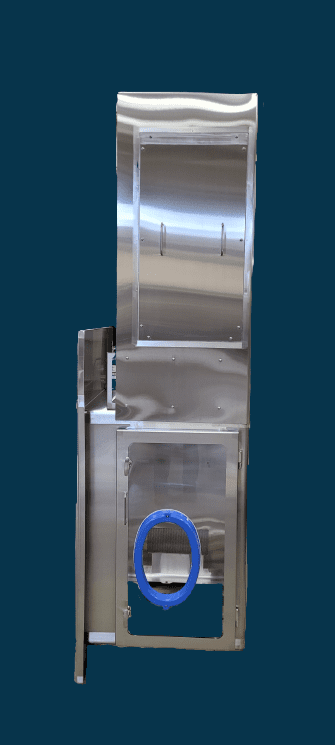

Intermediate Bulk Containers (IBC), also called “Bins”, are the industry standard for powder handling and processing applications where close containment is required. At Custom Powder Systems, we custom build these Bins and Bin Systems to precisely fit our customers’ needs.

Sometimes, however, it can be in a company’s best interest to spruce up an IBC they already have instead of investing in a brand new one. We talked to Rayce Gibson, a valued Sales Executive at CPS, about the benefits of refurbishing bins and how we can help with yours.

Handling it Your Way

Intermediate Bulk Containers handle powders from the raw material form to the point where it is either put into a package or made into tablets, capsules, or something similar. They are most often used in the chemical, food, pharmaceutical, and nutraceutical industries.

While these bins all essentially serve the same purpose, at CPS their fit and finishes are tailored to each company’s products. “Everything we do is built to the customer specifications or to their specific needs,” Rayce says. “All the equipment basically has the same starting point, and then everything is tweaked accordingly to fit whatever the customer requests.”

Reduce, Reuse, Refurbish

Having bins that don’t fit your current needs can really put a damper on the production process. However, not all companies have the resources to purchase new machines as frequently as they need fixing. At Custom Powder Systems, we believe there are many benefits to simply refurbishing the IBC you already have. Here’s just a few:

- Save Money – Purchasing equipment is often funneled through a capital expenditure process, which can sometimes deny funding for machines that just need repairs. Refurbishing your bins allows you to have like-new equipment that can come out of a maintenance budget for a much lower cost than buying a whole new piece.

- Save Time – It’s no secret that creating something great takes time, especially when you’re starting from scratch. And, in the world of manufacturing, time can often be your greatest asset. By fixing up your old bins, you can save your most precious resource by making a few quick tweaks instead of waiting to build something new.

- Environmentally Conscious – When replacing equipment, there will always be an element of waste production when it comes to disposing of the old and building the new. Simply making improvements to your existing bins is an environmentally-conscious decision that avoids the unnecessary use of excess materials.

- Maximize Investment – Picking out your equipment can be a big expenditure of both time and money, and you probably would like to avoid going through the exhausting process over and over again every time you need something new. By fixing or modifying the bins you already have, you can maximize your initial investment and avoid wasting more of your most precious resources.

- Process Modification – One of the most beautiful parts of engineering is the constant evolution of ideas. Over time, you may find new and better ways to manufacture your products, and you don’t want your equipment getting in the way of that. Being able to make adjustments to your current bins can make process modifications much more accessible.

Whether you purchased your bins from us or another manufacturer, we’d love to help you through the process of refurbishing.

“If you have bins that are damaged that you need to put back in service, send them to us!” Rayce says. “We’re more than happy to talk with anybody and everybody about doing the work to keep production quantities up that you may otherwise not be able to meet with damaged bins.”

It’s In the Name

We don’t call ourselves Custom Powder Systems for nothing. All of our products are designed specifically for the needs of each individual company because we know all the ins-and-outs of how the powder handling process works. We take great pride in being customer-centric and always providing the highest quality products.

“We work really hard as a team to find the best possible solution for the customer so we can make their lives easier and give them something that is going work,” Rayce says. “The greatest benefit we offer as a company is the extensive knowledge and experience of our teams.”

Whether you need a brand new bin or just a touch up on an old one, Custom Powder Systems is happy to work with you to create exactly what you’re looking for. Just give us a call, and let us know how we can help!

To learn more about Custom Powder Systems and the art of engineering, sign up for our newsletter.