We just returned from Detroit with our heads and hearts full of excitement for the additive manufacturing industry. Rarely have we seen such a neat combination of talent and passion!

Because we pride ourselves not only on our work in the additive manufacturing space, but in our relationships and processes, we thought you might find it interesting to see the notes we took/typed during our time in Detroit. Know that we’ll be working to add answers to these questions and solutions to these issues to Custom Powder’s additive manufacturing page in the coming days and weeks, but if you’re ready to talk now, please don’t hesitate to contact us today.

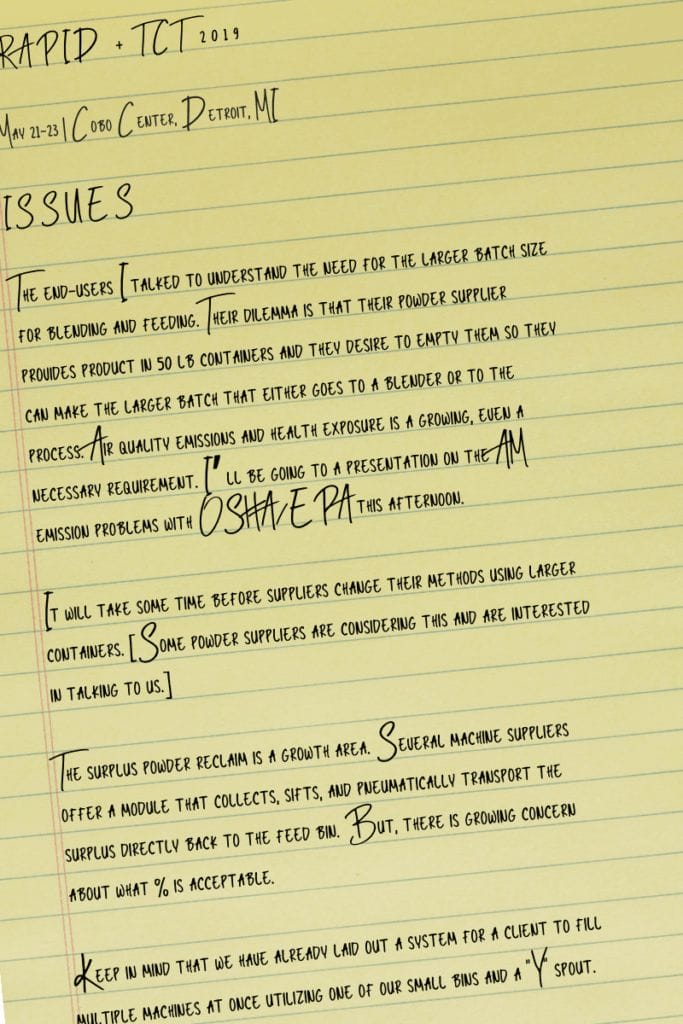

The end-users I talked to understand the need for the larger batch size for blending and feeding. Their dilemma is that their powder supplier provides product in 50 lb containers and they desire to empty them so they can make the larger batch that either goes to a blender or to the process. Air quality emissions and health exposure is a growing, even a necessary requirement. I’ll be going to a presentation on the AM emission problems with OSHA/EPA this afternoon.

The end-users I talked to understand the need for the larger batch size for blending and feeding. Their dilemma is that their powder supplier provides product in 50 lb containers and they desire to empty them so they can make the larger batch that either goes to a blender or to the process. Air quality emissions and health exposure is a growing, even a necessary requirement. I’ll be going to a presentation on the AM emission problems with OSHA/EPA this afternoon.

It will take some time before suppliers change their methods using larger containers. [Some powder suppliers are considering this and are interested in talking to us.]

The surplus powder reclaim is a growth area. Several machine suppliers offer a module that collects, sifts, and pneumatically transport the surplus directly back to the feed bin. But, there is growing concern about what % is acceptable.

I believe as volume increases, there will be a need to blend the surplus at a specific %. A system that can blend raw powder with the surplus reclaimed powder before feeding the AM process will soon be in demand.

As a side note, I have considerable experience with feeding either by LIW or Gain-in-weight multiple feed bins. It becomes more challenging as the number of feed bins increase. The end users I talked to are talking about 3 to 5 machines from one source feed bin.

Keep in mind that we have already laid out a system for a client to fill multiple machines at once utilizing one of our small bins and a “Y” spout.

Potential further questions are:

1). what will they do with excess materials?

2). What amount can they reclaim and what does that process look like? (most times they can screen and use some spent mixed with good material)

3). Problem with the 50lb bottles is a risk in completing a long run (48 +/-hours). If there is a gap caused by switch over, the product is potentially scrapped and the time wasted.

3.1) Anything larger containing the product, will have to be manipulated with a Lift capable of rotation as well as proximity to the machine. The material typically weighs 200+lb so a mobile lift will need to get up close and personal with the machine.

Bob Luebbe

—–Original Message—–

From: Chris Volz

Sent: Wednesday, May 22, 2019 11:09 AM

To: Bob Luebbe

Cc: Denise McIntosh

Subject: Other AM Ideas

Bob,

A challenge that AM end users talk to me about is how to empty currently supplied 50 lb containers of AM metals with less exposure to workers.

Also, what I’m hearing today in Conferences is the need to weigh dispense blended larger batch to multiple machines.

For these reasons:

(i) There is a need to improve quality by decreasing variability in end product part being produced.

(ii) decrease labor to pour smaller 50 lb containers for production machine

Another potential high growth area is engineered polymer compounds powder handling equipment. There is a major shortage of engineered compounds needed for 3D printing. Polymer/compounded will respond — we can provide solutions for the polymer compounded. I have some ideas already sketched.

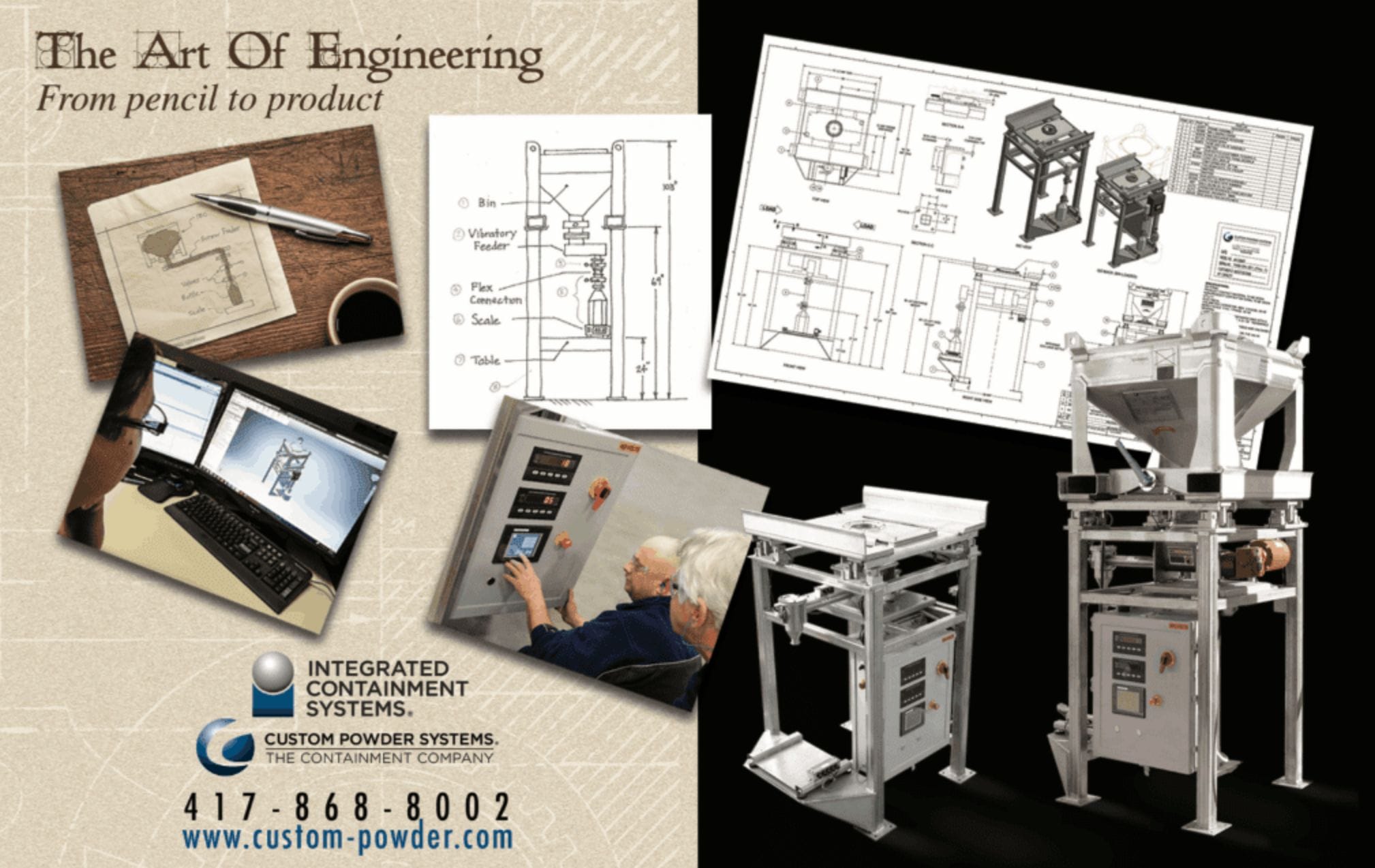

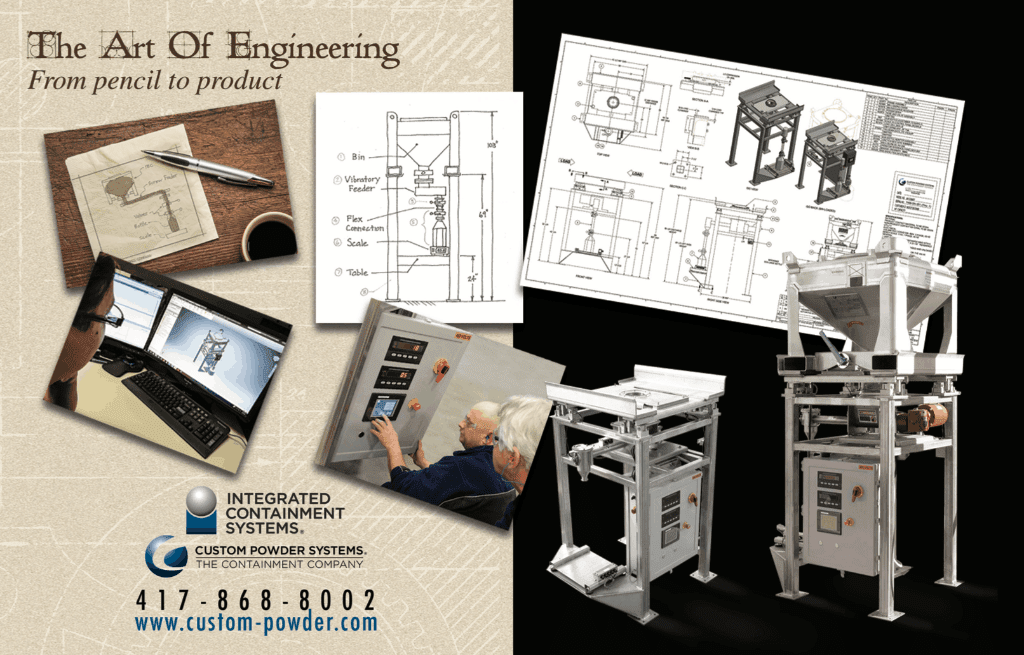

We’re proud to have Chris, Bob, and Denise on our team, and we’re also pretty fond of starting with sketches around here. Since we do so much custom work and every problem presents its own unique set of challenges, we’ve developed a pretty strong passion for napkin sketches. Some of the world’s greatest solutions started out the same way. If you’re interested in learning more about the why, hows, and whos of the ways we do the things we do, sign up here to receive our emails.