Utilizing the abilities of additive manufacturing (AKA 3D printing) with metal powders is unlocking the ability to build new parts and tools for aerospace, automotive, communications, and medicine that were previously not feasible. However, we must also consider and address the serious safety and handling implications.

Working with new technologies can be exciting, especially building more complex world exploration and communications tools.

Additive manufacturing (colloquially called 3D printing) is continuing to grow as a way to build more intricate and complex items that previously were not possible with traditional manufacturing methods.

Along with the potentially useful applications for this technology, it is also important to consider safety precautions and best practices to ensure the efficient handling of potentially dangerous materials.

What is Metal Powder Additive Manufacturing?

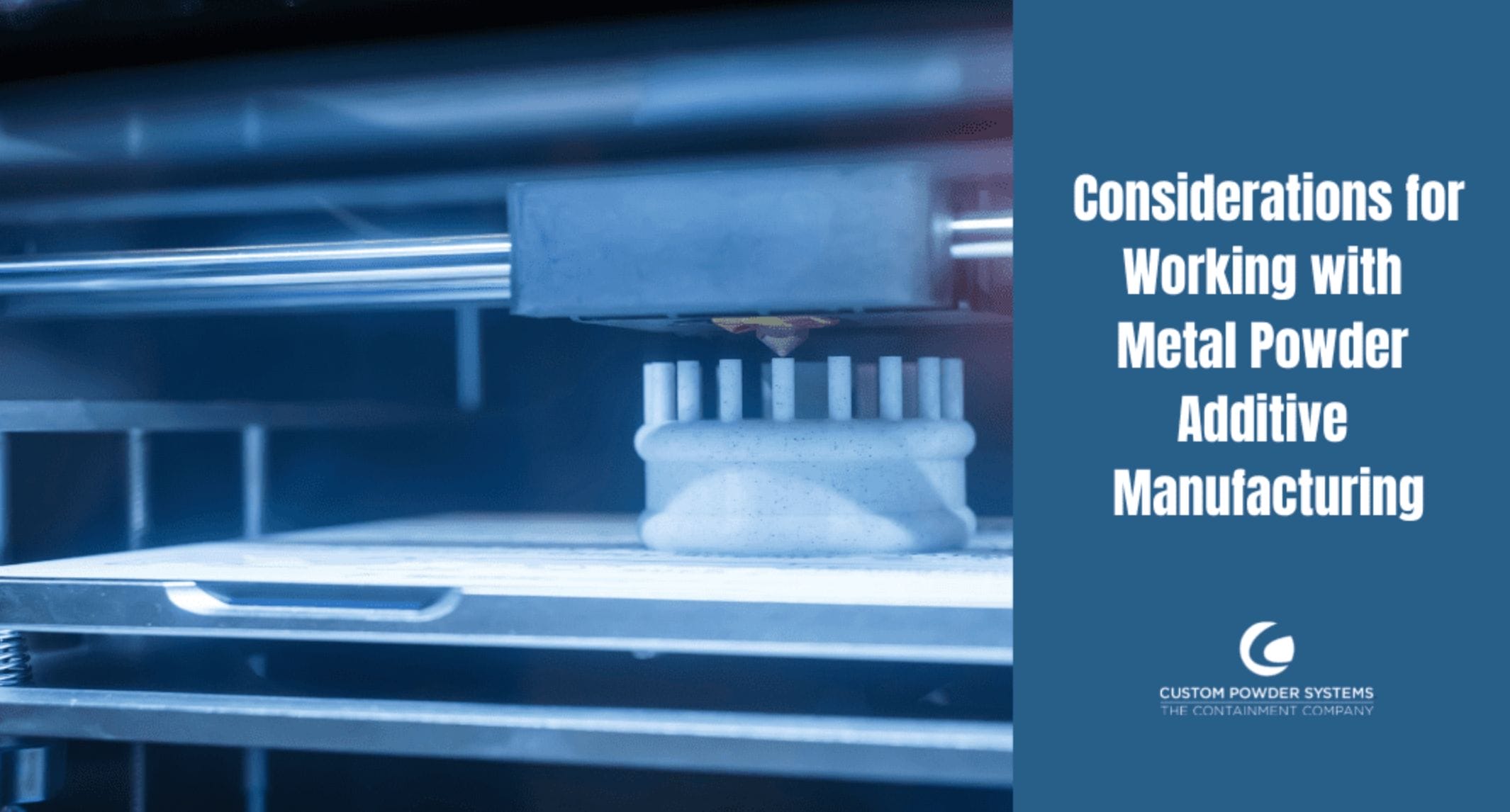

Additive Manufacturing is an incredible tool for building almost anything through a Computer-Aided Design (CAD) system. Traditional manufacturing can have limitations when working with metal to how existing sheets can be cut and molded. With additive manufacturing, designers can essentially start with a blank canvas and build whatever they like by adding one layer of material at a time. This allows for nearly unlimited ability to create completely customized pieces.

When working with metals, manufacturers utilize extremely fine powders of materials such as titanium, aluminum, nickel, and stainless steel. These powders are layered and joined together by fusing tools such as lasers, binders, and heated nozzles. Both the type of metals and methods used to build the final products depends on the manufacturer and what they are trying to create. Current uses for metal additive manufacturing include aerospace technology, car parts, medical devices, microwave communications, and satellite componentry.

What Does the Industry Currently Look Like?

Because the additive manufacturing industry is so new, many unknowns exist when predicting how the technology will develop in the coming years. Changes are occurring rapidly, sometimes making it challenging to keep up with new best practices. Unfortunately, this can also lead to some serious safety risks. Currently, there are no imposed regulations on the material handling.

Most companies utilizing additive manufacturing technologies are currently in the research and development phase, working mainly with homemade equipment and small batches. Because the materials are highly combustible, this can be dangerous if the powders are not handled properly. In general, current manufacturers in this space could benefit from improved containment solutions and a more in-depth understanding of what exactly they are dealing with.

What Can CPS Do?

At Custom Powder Systems, one of our greatest strengths is our ability to adapt to rapidly changing technologies. Our immense amount of combined knowledge on our teams allows us to embrace challenges, leading to incredible innovation. This can be especially valuable in a space with many manufacturers just starting in research and development phases of their endeavors. For those experiencing their first foray into commercial manufacturing with professional-grade machinery, we offer seamless integration of new components with already existing systems.

Due to the volatility of metal powders, they need to be handled safely. Many materials currently being used are pyrophoric powders, which will combust when exposed to oxygen at the submicron size. To prevent explosions, we offer inerting systems and O2 monitoring equipment. Additionally, the powders and gasses from the production process can be extremely harmful to the workers handling them. Our systems contain the materials in a way that isolates the products to prevent human exposure during powder handling and transferring.

One of the best parts about developing new technologies is expanding our knowledge base and developing new skills. At CPS, we take pride in our abilities to constantly learn and grow, no matter what we are dealing with. If you have a new area you’d like to explore, let us know how we can help!

To learn more about Custom Powder Systems and the art of engineering, sign up for our newsletter.