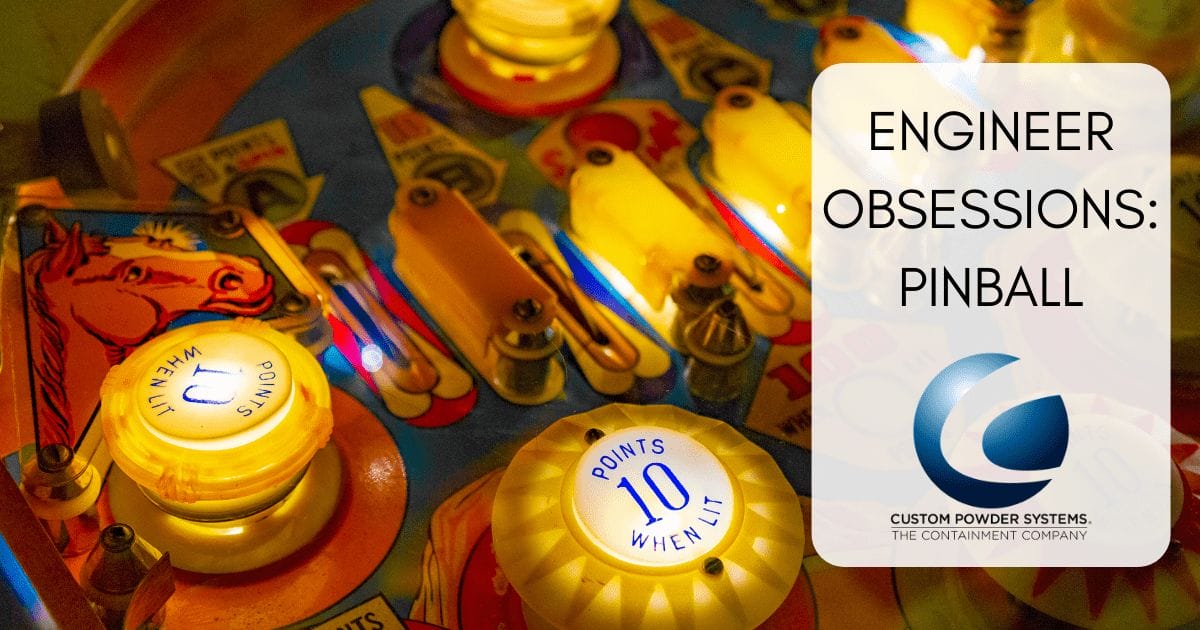

When engineers aren’t “engineering,” you’ll often find them building, tinkering, and inventing. Most engineers spend their days within a structured framework, but they’re always on the hunt for a creative outlet. Today, we profile Scott Heffern, Senior Vice-President of Products, about his after-hours obsession: Pinball Machines.

At Custom Powder Systems, we call upon our engineers to create simple solutions to complex problems, and Scott is one of our best. Since the beginning of CPS in 2005, he’s had a hand in many of our engineering developments, including aseptic isolation, bin/blend systems, and integrated process systems. But earlier this year we saw Scott at the Texas Pinball Festival grinning from ear-to-ear as he walked among over 400 pinball machines.

Scott’s obsession with pinball began when he was about eight. His family would head to Minnesota to go fishing, but he was more interested in staying back at the lodge mastering the games.

As the years went on, it was obvious his passion was more than just child’s play. He had the opportunity to purchase some arcade games and discovered his mechanical skills were perfectly suited for restoring old games. “I like the restoration as much as playing…probably even more,” Scott said.

While pinball has existed in some form since the 1700s, the contemporary version we know started its climb in the 1940s when flippers, bumpers, and electrification were introduced. The popularity reached a zenith in the 60s and 70s when pinball was such a national obsession that The Who wrote an entire rock-opera, giving us the hit song Pinball Wizard. As computerized games grew in popularity in the 1990s, the pinball industry was reduced to just one manufacturing company, but in the last decade, a resurgence has breathed new life into pinball.

At the Texas Pinball Festival, Scott isn’t just there as an attendee. He often brings his own restorations for others to try out and occasionally purchase. Like many hobbies, this isn’t a money-maker for Scott. Seeing others get the same pleasure from pinball he did as a kid is payment enough.

“They’re just starry-eyed. [People say], ‘I played this back in 1953!’” But there’s more than just nostalgia happening here. It quickly becomes a family event as kids enjoy the games just as much as their parents.

This wide range of engineering talent is what makes Scott Heffern a key part of Custom Powder Systems: “My strength at work is the mechanical design of our equipment.” When it comes to pinball machines, Scott tells us, “The mechanisms and the toys that are on them really fascinate me.”

When one of our customers encounters a new problem, we turn to Scott and his team to use their skills, experience, and personal passions to come up with a creative way to solve it… and sometimes knowing a little something about flippers, bumpers, or springs is the solution that’s needed!