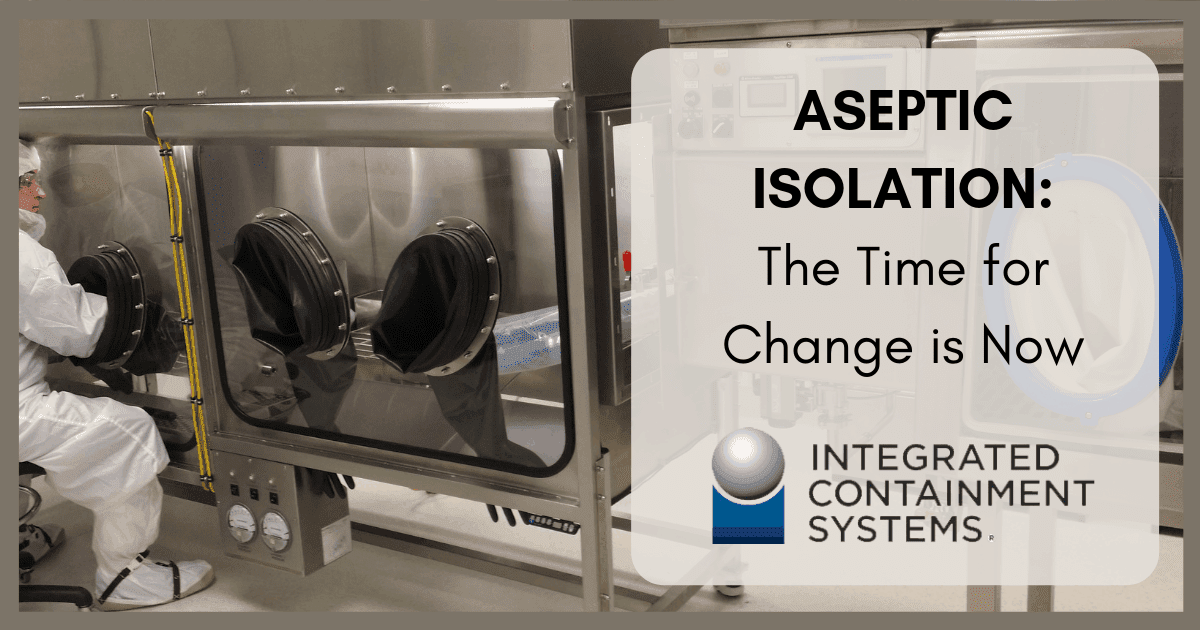

The meeting was held in December. Over 200 people attended a 2 1/2 day seminar hosted by the International Society of Pharmaceutical Engineers (ISPE). The takeaway? The time had come for aseptic isolation to come into its own.

The problem? The meeting happened in 1995.

Flash forward and we’ve only just begun to scratch the surface of what we can do with aseptic isolation. The question is, what took us so long to get started?

That answer is pretty simple — the technology wasn’t ready yet. The idea was solid, but failures caused delays. For many companies, especially those that had existing clean room implementations, the opportunity cost and associated risks to integrate an aseptic isolation system were simply too high.

But — if we can go out on a limb to say it — the time has come to kill off the clean room.

Death to the Clean Room

It’s important to note, first off, what aseptic really means, because this is the biggest area where clean rooms fail.

Aseptic isolation means keeping people out of the space, thereby limiting contamination or cross-contamination.

In fact, clean rooms are such a common point of failure that, when the Food and Drug Administration (FDA) walks in for an inspection, the inspector will bypass the isolation system and head straight to the clean room. The FDA has even gone so far as to take a stance, where the agency normally does not, in saying that aseptic isolation should be the new standard.

The fact of the matter is that clean rooms have points of failure that aseptic isolation systems do not. We live and operate in a world that is risk-averse. So even if the FDA is not saying “thou shalt use aseptic isolation systems”, the agency is acknowledging the inherent risks of clean rooms and giving guidance to avoid them.

That being the case, why is the FDA still approving clean rooms? The short answer is that people still want to use them. ROI is the primary concern, even if that ROI is only positive in the short term.

The Aseptic Advantage

The heart of the conversation is also the proverbial elephant in the room. Building and implementing aseptic isolation costs more money up front than building a clean room. But in most cases, those costs can be recouped many times over within a short period of time.

The arguments for spending the money come in many forms. First, there is less risk for lost batches. When your raw materials cost is in the hundreds of thousands of dollars for a single batch, losing one to a clean room failure is a tough pill to swallow.

Second to that, isolation systems require less space. In some cases, where the systems can be moved from one area to another, increased productivity alone is enough to justify the additional cost. We’re no longer tied to having all operations within a single location and forcing everyone to work inside of it.

This brings on another point that is often missed – operator satisfaction. An operator is able to use a glove box, rather than having to wear full protective equipment with their face and eyes covered. The rules of the surrounding room can be less stringent as well. In many cases, the room may only need to be kept at an ISO 7 level, rather than an ISO 5 and the required associated cleaning.

There is, of course, the associated time cost as well. Every time that you have to gown up to enter a clean room, you can bet on fifteen minutes. Then once you are ready to leave, there are another fifteen minutes involved. Add those thirty minutes, plus two breaks during a day, and then lunch. Suddenly the costs start to make a lot less sense when lost minutes turn into lost hours.

For those of you considering aseptic systems, there are other advantages that need to weigh on your decision. Not the least of these is the associated cost for running an aseptic system versus a clean room. Environmental controls, airflow, and maintenance all turn into money that you’re having to spend. With a closed, aseptic system, each of these factors experience a dramatic cost reduction.

Finally, it’s worth looking at the job of your quality assurance person. In days past, every operator in a clean room was another potential source for contamination. Further, compared to a clean room, the smaller size of an aseptic system allows for easier certification.

Answering Your Aseptic Questions

The three questions that we hear the most when it comes to aseptic systems have nothing to do with their capability. Anyone who has spent any time around clean rooms versus aseptic systems can tell you their advantages. What people do want to know is simple:

- What’s your aseptic isolation lead time?

- What accessories do you use?

- How much does aseptic isolation cost?

The simple answer for all three of these is “it depends.” The deeper answer is that it depends because we don’t believe in building cookie cutter solutions. We’d love to have a conversation about your situation to see how we can help and give you an idea of cost. We have built custom aseptic isolation solutions for customers from Iowa to Canada, and China to the east coast of the United States.

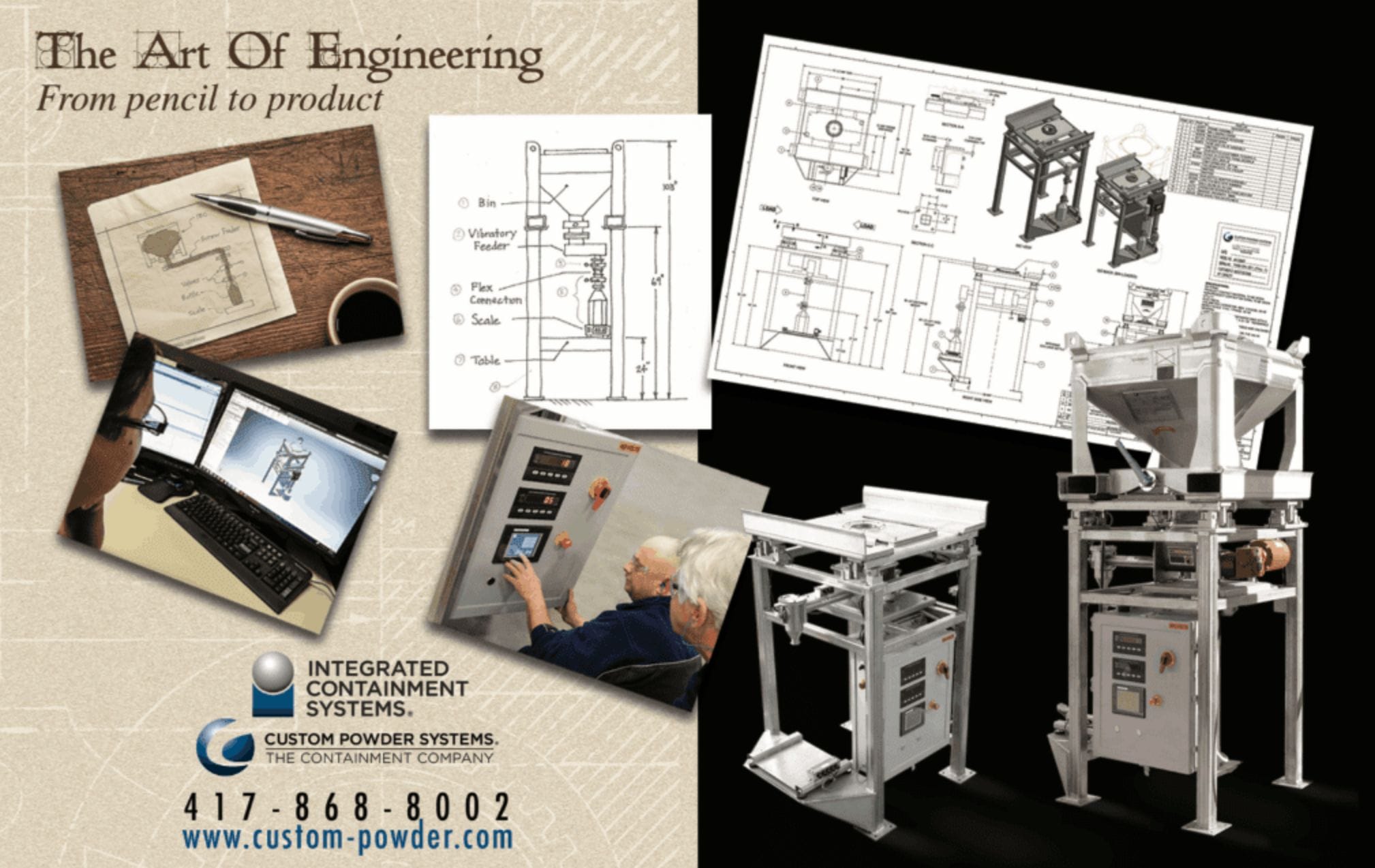

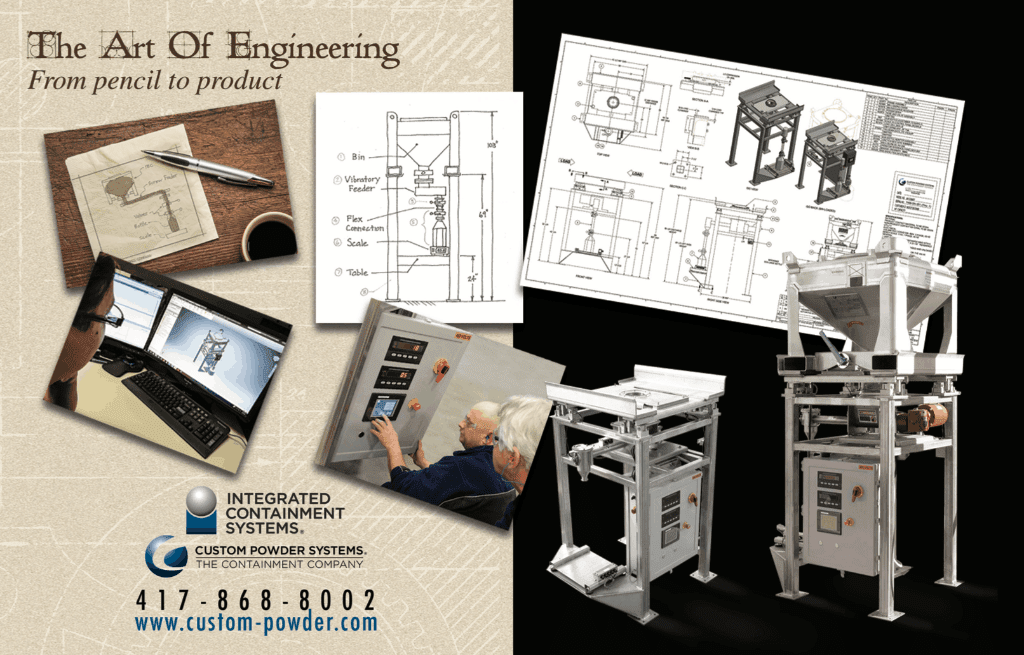

We are Integrated Containment Systems and Custom Powder Systems. We work with you to custom design the best solution to your problem, then build that design for you. And even better, because we’re based in the United States, we’re going to be there to fix a problem if something goes wrong.

What can we build for you today? Contact us and let us know.

“I congratulate Custom Powder Systems on winning a Safety Award of Merit,” said Edward Youdell, president and CEO of FMA. “Safety is clearly a priority for the company. They set a good example for others in the industry. FMA and CNA are proud to recognize all our safety award winners.”

“I congratulate Custom Powder Systems on winning a Safety Award of Merit,” said Edward Youdell, president and CEO of FMA. “Safety is clearly a priority for the company. They set a good example for others in the industry. FMA and CNA are proud to recognize all our safety award winners.”