Understanding Downflow Booths, Isolators, and Custom Containment Solutions—And How to Meet OEL Challenges Head-On

In high-stakes industries like pharmaceutical, biotech, and chemical manufacturing, managing the risks of potent compound exposure is essential. Custom Powder Systems specializes in the design and engineering of containment solutions that help clients meet strict Occupational Exposure Limits (OELs) while maintaining productivity and compliance.

As a domestic supplier, Custom Powder Systems proudly designs, fabricates, and supports all solutions in the United States—offering faster communication, responsive service, and complete control over quality and timelines.

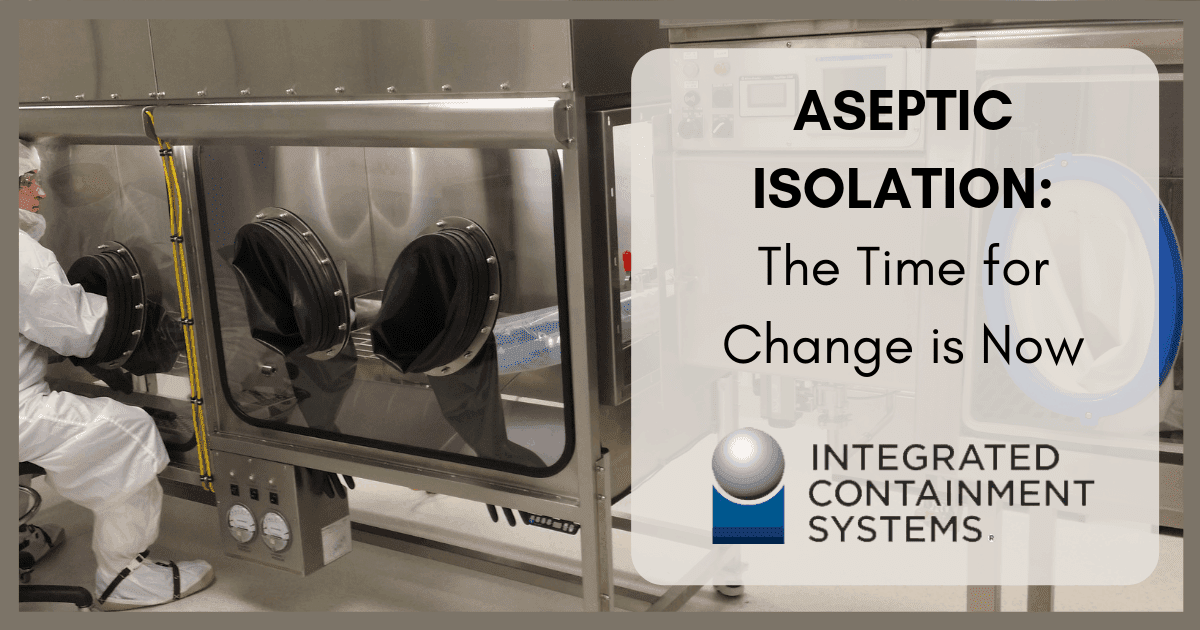

We also collaborate closely with our sister company, Integrated Containment Systems (ICS), to deliver complete, end-to-end solutions for high-containment environments. ICS enhances our capabilities by focusing on the development of isolators, gloveboxes, and specialty enclosures tailored to critical applications.

This guide breaks down three core technologies—downflow booths, isolators, and custom systems—and how they address common challenges in regulated environments.

Downflow Booths: Flexible and Effective Containment

Custom Powder Systems’ downflow booths are ideal for handling dust-generating processes such as weighing, dispensing, or sampling APIs. These booths use unidirectional (laminar) airflow, HEPA filtration, and low-level extraction to protect both the operator and the surrounding environment.

Key Features:

- Modular stainless-steel construction with powder-coated interiors

- HEPA or ULPA filtration for particle capture

- Airflow design maintains ISO Class 5–8 conditions

- Available with integrated weighing stations and ergonomic work surfaces

Best suited for:

OEL targets down to 1 µg/m³, suitable for non-sterile operations that require open access.

Advantage:

Compared to full enclosures, downflow booths offer operational flexibility, faster access, and lower capital expenditure—all while achieving excellent containment performance for medium-potency compounds.

Isolators: Maximum Protection for Highly Potent Compounds

When dealing with HPAPIs (highly potent active pharmaceutical ingredients) or cytotoxic materials, isolators are the gold standard. Custom Powder Systems designs both negative and positive pressure isolators depending on the containment or sterility requirement.

Design Attributes:

- Fully sealed environments with glove ports

- Integrated decon systems for aseptic cleaning

- Internal pressure differential controls

- Optional vaporized hydrogen peroxide (VHP) sterilization

Typical Applications:

- Final weighing of HPAPIs

- Sterile material transfer

- Aseptic sampling or QC labs

With containment capability <1 µg/m³, isolators are engineered to protect both personnel and product without compromise.

Custom Systems: Engineered for Specific Process Demands

Every process is different. That’s why Custom Powder Systems offers engineered solutions tailored to individual client needs—from transfer systems to lift-and-seal devices, and IBC blending enclosures.

Every process is different. That’s why Custom Powder Systems offers engineered containment solutions tailored to individual client needs—from transfer systems to lift-and-seal devices, and IBC blending enclosures.

Examples include:

- Split Butterfly Valve (SBV) charging systems

- Contained drum-to-IBC transfers

- Lift-assist isolator integrations

- Contained tablet dedusters or blenders

Process-specific benefits:

- Seamless containment during powder charging/discharging

- CIP/SIP compatibility for hygiene-critical operations

- Compact footprints designed to retrofit existing facilities

How We Solve Common OEL Compliance Challenges

1. Inconsistent Airflow or HEPA Efficiency

We integrate real-time airflow monitoring and redundant HEPA filtration to ensure consistent negative pressure and ISO classification—even during high-traffic operation.

2. Difficult-to-Clean Surfaces

All containment systems are designed with cleanability in mind: smooth welds, sloped surfaces, and CIP-ready connections minimize risk and downtime.

3. Cross-Contamination Risks

Our closed transfer systems—like IBC charging stations with vacuum conveying or split-valve containment—prevent powder breach during critical transfer points.

4. Operator Fatigue or Workflow Disruption

Human factors are considered in every design, from ergonomically placed glove ports to adjustable-height work surfaces—reducing strain while increasing precision.

A Partnership for Compliance and Confidence

And because we’re a U.S.-based partner, we provide unmatched access to engineering teams, faster service turnarounds, and ongoing domestic support—without navigating international delays.

Together with Integrated Containment Systems, we offer a unified approach to containment that’s both technically sound and tailored to your operation’s needs.

Let’s Design a Safer, Smarter Process

Explore our downflow booths, isolators, and engineered containment systems at custom-powder.com, or contact our team to start your compliance roadmap today.