Once in a while, we will read an article that reminds us of the challenges that face not only us, but also our customers. Since NASA has been a customer of ours in the past (did you know that moon rocks are handled inside of a gloved isolation box that was designed and built by Custom Powder Systems?), the recent story of their failed rocket launch hit close to home. Not because of the rocket, but because of what caused the failure.

As Bloomberg reports, an Oregon supplier for NASA had been falsifying test results and providing faulty materials to the agency for over 19 years. The result? Over $700 million in losses, charged to the U.S. taxpayers.

NASA’s Director for Launch Services called out the problem in plain English.

NASA relies on the integrity of our industry throughout the supply chain.

Integrity is doing the right thing, even when no one is looking, and it’s the difference between being able to solve a problem, or creating a new one.

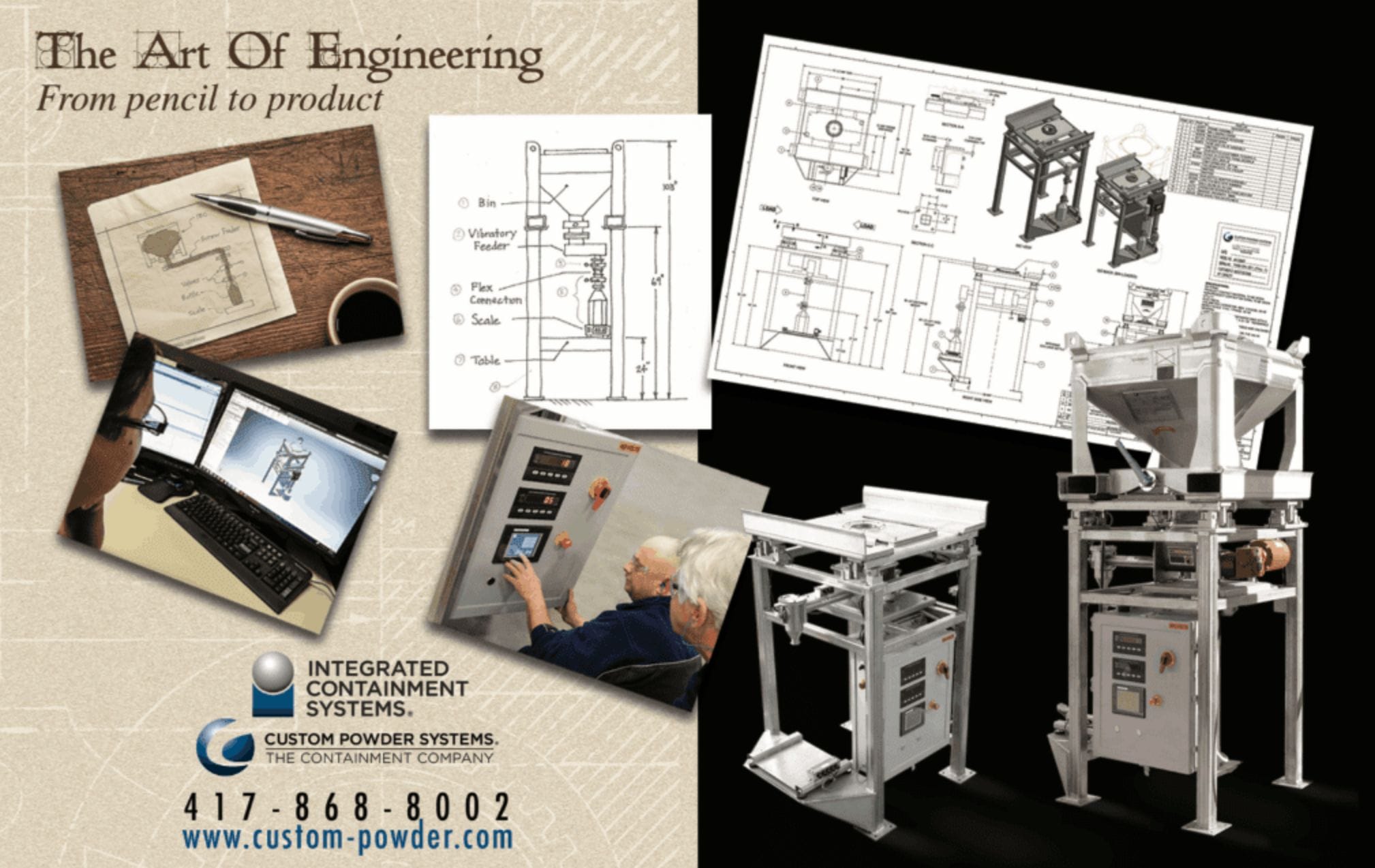

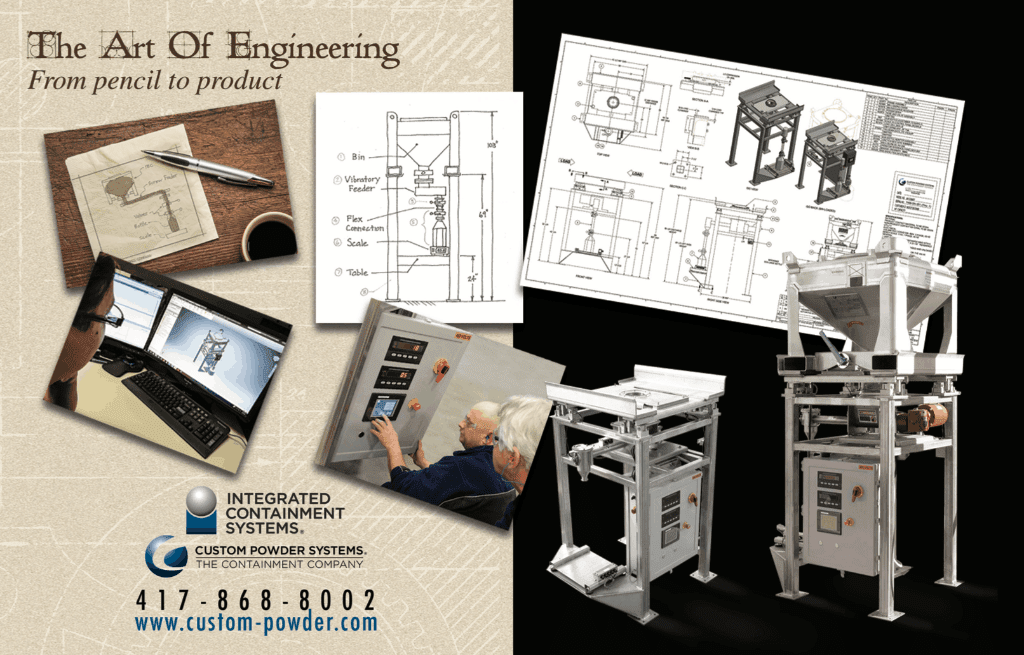

What does it take to build a great product, and do so with integrity? As far as we can tell, it takes a hard day’s work and an honest desire to help your customer succeed.

Some folks say that makes us different. But if you’re asking us, it’s just the way that things should be done.

As we keep helping more people, our business grows to meet their needs. When we’re looking for a new welder, project manager, or shop maintenance person, we seek out exceptional people who understand the challenges that we solve without sacrificing the quality standards we put in place.

Your success is too important for us to settle for anything less.

We’re fortunate to have hired some of the best people in the world from right here in Missouri. At the end of the day, we’re not only building custom projects, but we’re also building relationships for the long term. You can bet that every member of our Custom Powder team will do what’s right, work hard for you, and never try to take a shortcut.

If this sounds like you, we’re hiring, and we’d love to talk to you.